When it comes to electrical safety, every building — whether it’s a cozy home or a sprawling factory — needs a secure system to manage and distribute power. This is where the electrical distribution box steps in. Also known as a distribution board or breaker panel, it acts as the control hub, distributing power to different circuits and protecting them from overloads and faults. Here, we’ll delve into what an electrical distribution box is, how it works, the components inside, types, and what to consider when choosing one.

1. Understanding Electrical Distribution Boxes

An electrical distribution box is often called the control hub of a building’s electrical system, and for good reason. It’s where power from the main supply splits into different circuits that feed lights, appliances, and equipment throughout the building. Think of it like a conductor in an orchestra: it keeps everything coordinated and running smoothly while preventing problems like overloading or short-circuiting.

What is an Electrical Distribution Box?

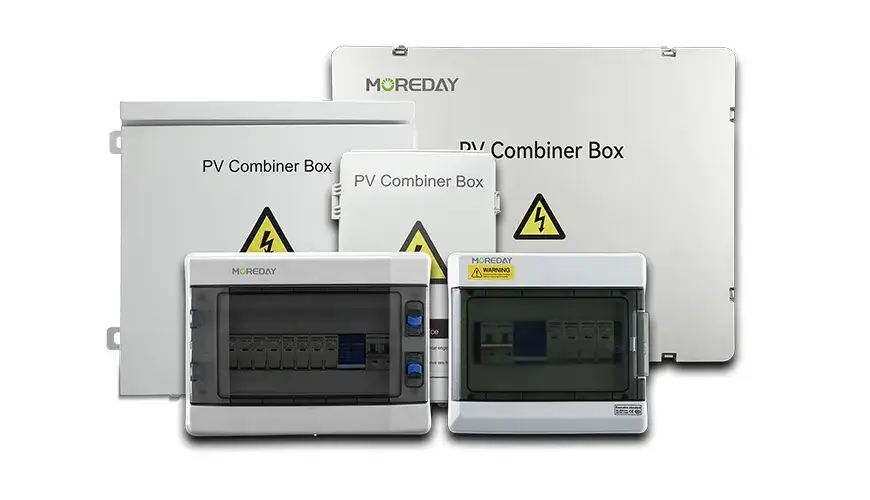

At its core, an electrical distribution box (or distribution board) is a metal or plastic enclosure that houses various components responsible for managing and distributing electricity across different circuits. This setup allows electricity to be distributed safely and efficiently, whether it’s for a home with basic lighting and outlets or a manufacturing plant with heavy machinery.

In addition to distributing power, the box also acts as a safety mechanism. If there’s an issue, like a power surge or short circuit, the distribution box’s circuit breakers or fuses will “trip” — shutting down the affected circuit. This quick response prevents damage to devices and, more importantly, reduces the risk of electrical fires, making it an indispensable part of any safe electrical system.

The Role of Distribution Boxes in Different Settings

Distribution boxes vary widely based on their application and the environment they’re used in:

- Residential: In homes, distribution boxes are typically smaller and handle standard circuits for lighting, outlets, and basic appliances. They don’t need to manage heavy loads but still play a vital role in preventing electrical faults that could lead to fires.

- Commercial: For offices and commercial buildings, distribution boxes are designed to handle more circuits and moderate power demands, accommodating lighting, computers, air conditioning units, and other equipment. They often feature sub-panels to help manage power distribution more effectively.

- Industrial: In industrial environments, distribution boxes take on an even more significant role, dealing with high voltage and substantial electrical loads from large machinery. These boxes often include additional protection components like surge protection devices (SPDs) and may be paired with transformer boxes to help stabilize power for high-load areas.

Why Distribution Boxes are Essential

The main purpose of an electrical distribution box is to organize and protect. It ensures each part of a building gets just the right amount of power without risking overload. This setup isn’t just for convenience; it’s also about safety. A well-designed distribution box:

- Prevents Overloads: When too many devices run on the same circuit, there’s a risk of overheating, which can cause fires. The distribution box helps distribute load evenly across different circuits, preventing overload.

- Protects Against Short Circuits and Surges: With built-in circuit breakers and fuses, it immediately cuts off power to any faulty circuit, preventing potential hazards.

- Keeps Power Organized: Instead of a messy web of wires running through the walls, all power connections lead back to the distribution box. This organization makes it easier to monitor, maintain, and troubleshoot circuits.

2. Components Inside an Electrical Distribution Box

Opening up an electrical distribution box might look like stepping into a maze of wires, switches, and mysterious gadgets. But each component plays a vital role in keeping electricity flowing safely and smoothly. Let’s break down these essential parts to understand how they work together to distribute and protect power across a building.

Circuit Breakers

At the heart of any distribution box are the circuit breakers. These are like the box’s soldiers, standing guard over each circuit to prevent overloading, overheating, and short-circuiting. Here’s a closer look at how they work and the types commonly used:

- Function of Circuit Breakers: When a circuit draws too much current or encounters a fault, the circuit breaker “trips” and cuts off the flow of electricity. This trip mechanism prevents potential hazards like fires or electrical damage to connected devices. By interrupting the power flow, circuit breakers act as automatic switches that restore safety in seconds.

- Types of Circuit Breakers:

- Thermal Circuit Breakers: These respond to excessive heat. When a circuit becomes overloaded, heat builds up, causing the breaker’s internal mechanism to trip.

- Magnetic Circuit Breakers: These use electromagnetic force to detect high currents quickly, often used in settings where rapid response is essential.

- Thermal-Magnetic Circuit Breakers: Many distribution boxes use these, as they combine the fast response of magnetic breakers with the longer-duration overload protection of thermal breakers.

Each circuit breaker in the distribution box corresponds to a different circuit, like a lighting circuit, an appliance circuit, or a specialized area like a kitchen or garage. By isolating each circuit, they make it easy to cut power to specific areas without affecting the entire system.

Fuses

While less common in modern distribution boxes, fuses are still widely used in certain setups, especially where quick reaction times are needed to protect sensitive electronics. A fuse is a single-use component designed to sacrifice itself to save the circuit.

- How Fuses Work: Inside each fuse is a thin metal filament. When an overload occurs, this filament heats up and melts, breaking the circuit instantly. The fuse must then be replaced, unlike a circuit breaker that can simply be reset.

- Applications for Fuses: Fuses are commonly found in distribution boxes that protect highly sensitive or critical equipment, as they react faster than many types of breakers, offering an additional layer of security for electronics.

Surge Protective Devices (SPDs)

Every building is vulnerable to power surges — sudden increases in voltage that can damage appliances, electronics, and wiring. Surge Protective Devices (SPDs) are there to absorb and divert these excess volts safely, acting like a shock absorber for the distribution box.

- How SPDs Work: When a surge occurs, SPDs kick in to reduce the excessive voltage by channeling it safely to the ground wire. This rapid absorption helps protect circuits from damage that could result from spikes caused by things like lightning strikes, power outages, or the startup of heavy machinery.

- Types of SPDs:

- Type 1 SPD: Used in main panels to protect against external surges, such as those from lightning.

- Type 2 SPD: Typically found in sub-panels, protecting against surges from within the building’s electrical system, like those caused by large appliances.

- Type 3 SPD: Plugged directly into outlets to protect individual devices, often seen in residential settings.

Switches and Connectors

While circuit breakers and fuses control the power flow, switches and connectors make it easy to manage and maintain the box. The main switch is often located at the top, allowing users to quickly shut off all circuits in an emergency.

- Main Switch: This is the “master control” for the entire distribution box, allowing the entire system to be turned off or on. In an emergency, flipping this switch cuts power to all circuits immediately, ensuring that maintenance and troubleshooting can be done safely.

- Bus Bars and Connectors: Bus bars are flat strips of metal, usually made of copper or aluminum, that act as connection points for the various circuits within the distribution box. Neutral and ground wires connect to their respective bus bars, helping maintain stability and safety in the system. Connectors, on the other hand, ensure the wires are securely attached to these bus bars, providing reliable connections.

Meters (Voltage, Current, Energy)

In larger distribution boxes, you might find meters to monitor and measure the electrical parameters. These meters are critical for understanding the performance and usage of the electrical system:

- Voltage Meter: Measures the pressure of electricity, indicating whether the distribution box is delivering adequate voltage across circuits.

- Current Meter: Tracks the amount of electricity flowing through the circuits. By monitoring amps, the current meter helps identify circuits that might be drawing too much power, which can lead to overheating or potential faults.

- Energy Meter: Measures overall electricity usage, providing valuable data for tracking energy consumption. This meter is useful for commercial and industrial users aiming to optimize energy use, reduce costs, and improve efficiency.

Residual Current Devices (RCDs)

In addition to circuit breakers, many distribution boxes include Residual Current Devices (RCDs) for added protection. Unlike standard breakers that respond to overloads, RCDs are sensitive to changes in electrical flow that could indicate a potential shock hazard.

- Function of RCDs: RCDs monitor the current flowing into and out of a circuit. If there’s even a slight difference, such as from a fault where current could be leaking to the ground (a sign of potential electric shock risk), the RCD will cut off the power immediately.

- Types of RCDs:

- Fixed RCDs: Installed in the distribution box to monitor whole circuits.

- Socket-Outlets with RCDs: Offer protection at specific outlets, common in high-risk areas like kitchens or bathrooms.

RCDs are especially useful in environments where electrical shock is a higher risk, such as in commercial kitchens, workshops, or outdoor areas where water exposure might occur.

Enclosure and Insulation Materials

The enclosure (or the outer shell) of the distribution box is a critical safety feature. It’s designed to protect the components inside from environmental factors and accidental contact. Made of durable materials like metal or fire-resistant plastic, the enclosure keeps dust, moisture, and physical impacts from interfering with the box’s operations.

- Insulation Materials: Inside the box, various insulating materials protect wires and connections from moisture and contaminants. Insulation also helps keep the box cool, which is crucial for high-load environments where components might overheat.

Grounding System

The grounding system is another essential component that protects the box and the people around it from electric shock. Every distribution box connects to a ground wire, which provides a safe path for stray electrical currents to flow into the earth instead of through circuits or appliances.

- Ground Bus Bar: The ground bus bar within the distribution box is where all ground wires connect. It ensures that, in case of a fault, the electrical current safely diverts away from the circuits and reduces the risk of shock.

Grounding is particularly crucial for larger setups or in industrial settings, where higher voltages are in use, and the risk of shock is more significant.

3. Types of Electrical Distribution Boxes

Distribution boxes come in many shapes and sizes. Here’s a look at some common types and their specific roles.

Main Circuit Breaker Panel

This is the primary panel for any building. It’s the first stop for power coming from the main supply, where it’s split into various circuits. If there’s a big fault, this panel is where everything can be shut off. It’s the powerhouse of the entire setup.

Sub-Panel

Ever notice an additional breaker panel in certain rooms, like a garage or office space? That’s a sub-panel. These are smaller, localized panels that help distribute power to specific areas, making it easier to manage and reducing the load on the main panel.

Fuse Box

Fuse boxes are an older form of distribution but still useful in certain scenarios. Instead of tripping like breakers, fuses blow when there’s a fault. They’re quick and protect sensitive electronics from sudden surges.

Transfer Switch

A transfer switch lets you switch between two power sources, like the main power and a generator. When the main power fails, the transfer switch kicks in to connect to a backup. Hospitals, for instance, rely on automatic transfer switches to keep the lights on during emergencies.

4. Key Material Requirements for Distribution Boxes

Durability is essential for any distribution box, but what materials make it reliable? Here are the key considerations:

1. Impact and Flame Resistance

Materials need to withstand physical knocks and resist catching fire. Most boxes use polycarbonate or metal for strength and fire resistance. For example, if the box is in an industrial area, where it might face more physical stress, stronger enclosures help ensure longevity.

2. Leakage and Surge Resistance

Electricity should flow smoothly within the box, without leaks or surges that could compromise safety. Quality boxes feature insulation and seals to protect against moisture and prevent accidental contact with live parts.

Related Reading: Key Material Requirements for Distribution Boxes

5. Choosing the Right Distribution Box for Your Needs

Not all distribution boxes are the same, so selecting the right one is crucial. Here are some points to consider:

Sizing and Capacity

Think about the current and future power needs. The size and number of circuits in the distribution box should match your needs. If you’re powering a large office, a higher-capacity box with multiple circuit options will be essential.

Safety Compliance

Look for boxes that meet regulatory standards. Many countries require boxes to have UL (Underwriters Laboratories) or CE certification to ensure safety.

Additional Features

Do you need surge protection? RCDs (Residual Current Devices) for added safety? Consider these features to ensure your distribution box is future-proofed for any situation.

Related Reading: Choosing the Right Distribution Box for Your Needs

6. Installation and Safety Guidelines

While it’s best to have a professional electrician handle installation, here’s an outline of the process for those interested:

1. Pre-Installation Planning

Start by assessing the space, load requirements, and safety considerations. Measure where the box will be mounted, making sure it’s accessible and safe from water or heavy impact.

2. Mounting the Distribution Box

Securely attach the box to a stable surface, typically a wall. Use screws or brackets to keep it steady and at a height where breakers can be easily reached.

3. Wiring and Testing

An electrician will connect the mains power to the distribution box, then branch out from there to different circuits. Once everything’s wired, testing ensures the breakers trip correctly, and everything is up to code.

Why Hire a Professional?

Improper installation can lead to dangerous situations. A qualified electrician ensures that everything’s grounded correctly, complies with local codes, and functions smoothly.

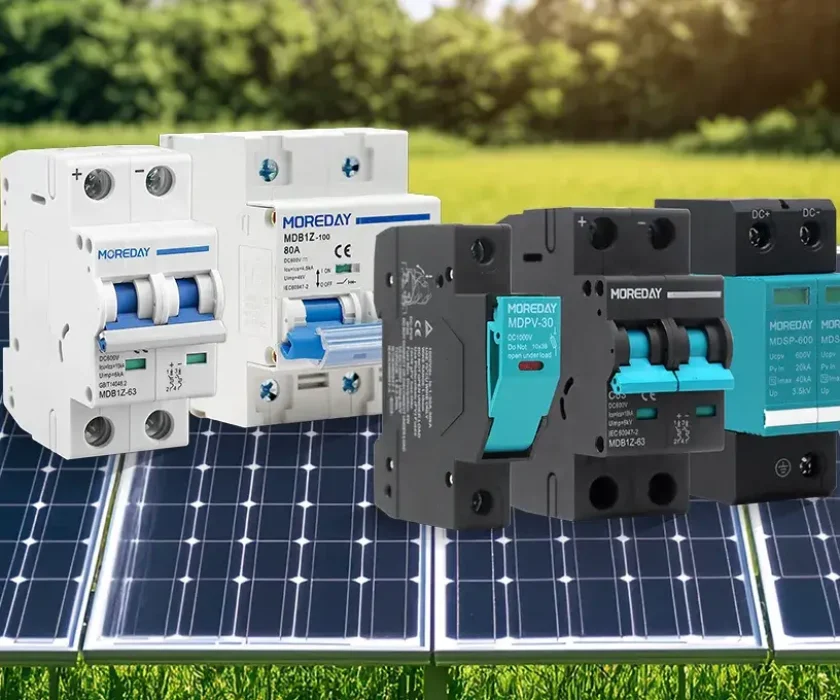

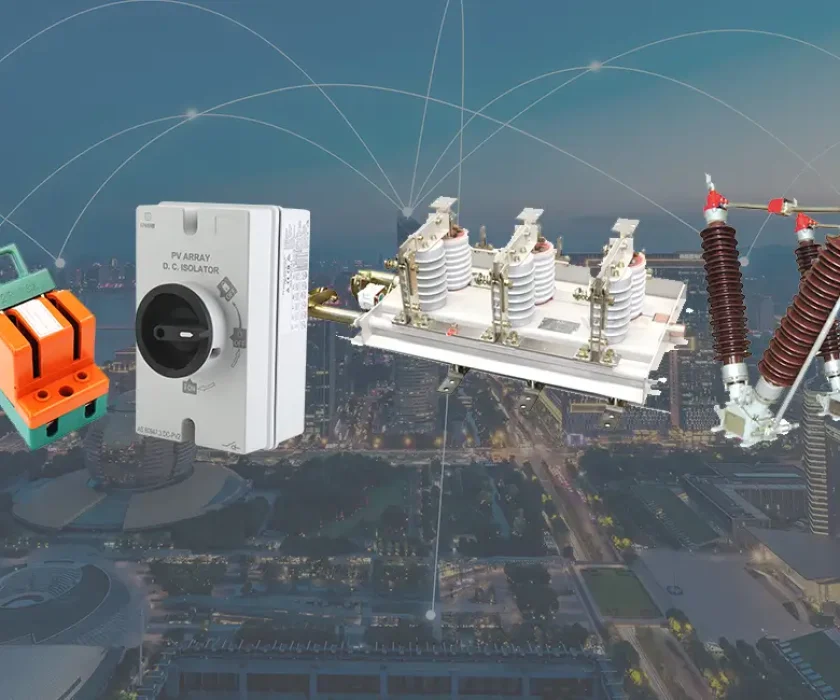

7. MOREDAY’s Expertise in Distribution Boxes

As a professional distribution box manufacturer based in China, MOREDAY brings expertise, quality, and customization to every product. From simple residential distribution boxes to complex industrial solutions, MOREDAY designs products that meet rigorous standards. Our boxes feature high-grade materials, cutting-edge designs, and custom solutions to cater to your unique power needs. We focus on safety, reliability, and ease of use, making us a trusted choice in distribution equipment.

8. Conclusion

In the world of electrical safety, distribution boxes are essential. They’re the unsung heroes that keep your building’s electrical flow organized, safe, and efficient. By choosing the right box and having it installed professionally, you ensure that your power needs are met safely and effectively. Whether you’re setting up a home or managing a large industrial site, distribution boxes from MOREDAY provide the reliability and security you need.

FAQs

1. What is the difference between a consumer unit and a distribution board?

A consumer unit is mainly used in homes and small spaces, while a distribution board is for more significant power loads in commercial or industrial setups.

2. How often should I check or maintain my distribution box?

Regular maintenance is essential. It’s recommended to check it annually or whenever you experience issues like frequent tripping.

3. What type of distribution box is best for a small business?

For small businesses, a main circuit breaker panel with a sub-panel for specific high-load areas, like a server room, works well.

4. Can I install an electrical distribution box myself?

Unless you’re a qualified electrician, it’s best to leave the installation to a professional to ensure safety and code compliance.

5. What’s the average lifespan of a distribution box?

A well-maintained distribution box can last 20-30 years. Regular inspections can help extend its lifespan and keep it running safely.