U

nderstanding Miniature Circuit Breakers (MCBs) is crucial for anyone involved in electrical systems, whether you’re a professional electrician, a homeowner, or a business owner. MCBs play a vital role in safeguarding electrical circuits from damage caused by overloads or short circuits. However, not all MCBs are created equal, and knowing the differences between AC MCBs (Alternating Current Miniature Circuit Breakers) and DC MCBs (Direct Current Miniature Circuit Breakers) is essential for selecting the right one for your specific needs.

In the modern world, electrical systems are the backbone of almost every aspect of life. From powering homes and businesses to running complex industrial machines and renewable energy systems, the demand for reliable and safe electrical components is higher than ever. MCBs are at the forefront of this demand, ensuring that electrical circuits operate safely and efficiently. They are designed to detect anomalies in electrical current, such as surges or faults, and interrupt the flow of electricity to prevent potential damage or hazards.

This article aims to demystify the differences between AC MCBs and DC MCBs by exploring their unique characteristics, how they work, and where they are best applied. By the end of this comprehensive guide, you’ll have a clear understanding of which type of MCB is suitable for your particular application, whether it’s in a residential setting, a commercial environment, or a specialized industrial scenario.

What is an MCB?

Definition and Purpose: A Miniature Circuit Breaker (MCB) is an essential electrical device designed to protect electrical circuits from damage caused by overloads or short circuits. Unlike traditional fuses, which must be replaced after a single use, MCBs can be reset manually after they trip. This feature makes them more convenient and cost-effective in the long run.

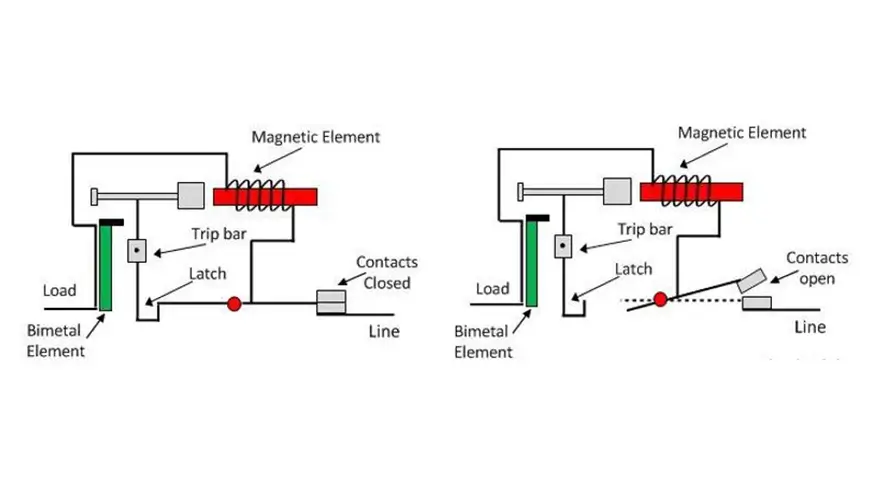

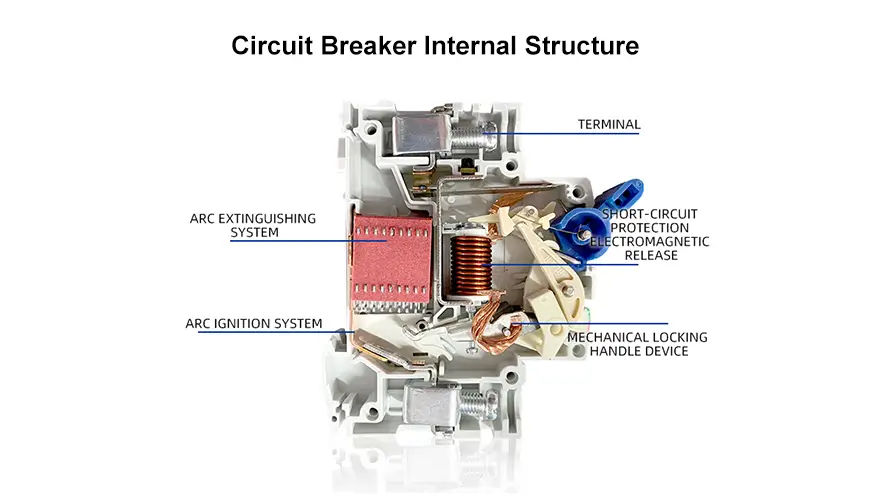

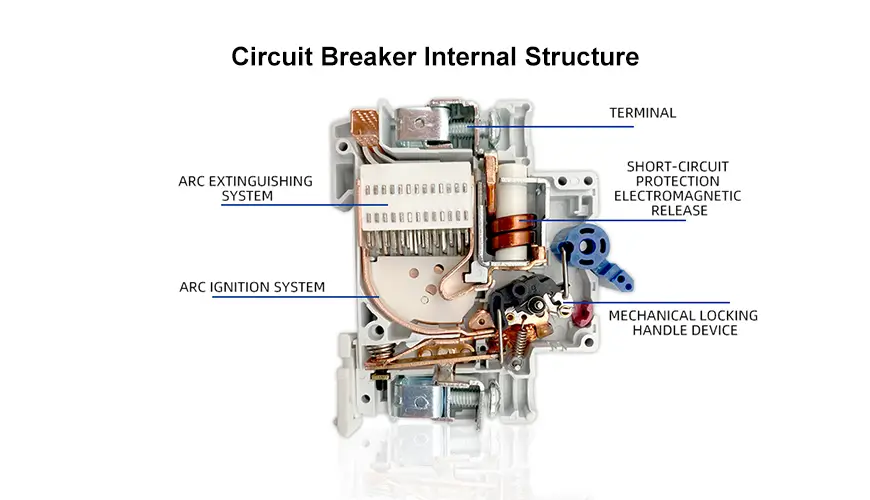

General Working Principle: The operation of an MCB is based on two primary mechanisms: the thermal mechanism and the magnetic mechanism.

Thermal Mechanism: This mechanism consists of a bimetallic strip that bends when it heats up due to the flow of excessive current. The bending of the strip eventually triggers the tripping mechanism, which breaks the circuit and stops the flow of current. This process is relatively slow, allowing the MCB to respond to prolonged overcurrent conditions. It ensures that temporary surges or spikes do not cause unnecessary trips, maintaining the stability of the electrical system.

Magnetic Mechanism: The magnetic mechanism responds to short circuit conditions, where the current rises very rapidly. It comprises a solenoid or an electromagnet that generates a magnetic field when high current flows through it. This magnetic field activates a trip lever, which immediately disconnects the circuit. This response is instantaneous, protecting the circuit and connected devices from the damaging effects of short circuits.

Advantages of Using MCBs: MCBs offer several advantages over traditional fuses and other circuit protection devices:

Resettable: Unlike fuses, which must be replaced after they blow, MCBs can be easily reset by simply flipping a switch. This feature reduces maintenance costs and downtime.

Enhanced Safety: MCBs provide reliable protection against both overload and short circuit conditions, ensuring the safety of electrical installations and reducing the risk of fire and equipment damage.

Precision: MCBs are designed to trip at specific current levels, providing precise protection for electrical circuits. They can be selected based on the specific requirements of the circuit they protect.

Durability: MCBs are built to withstand multiple trips and resets, offering long-term reliability and performance.

Types of MCBs

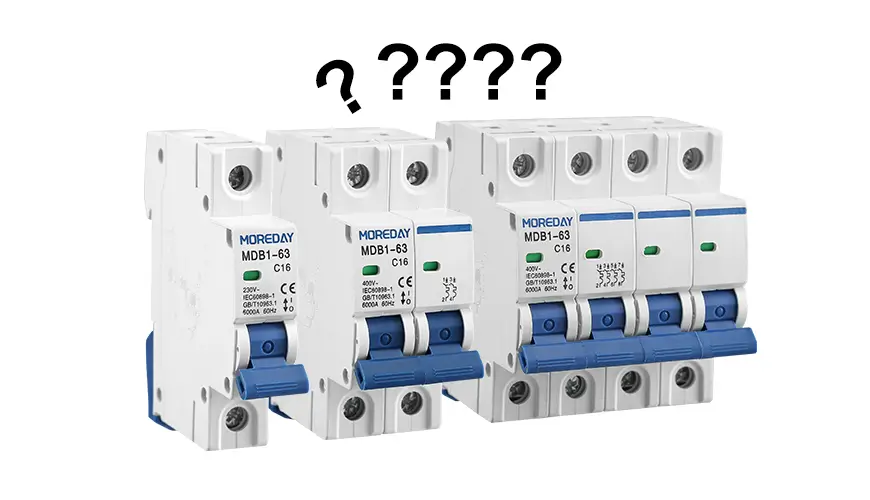

AC MCB (Alternating Current Miniature Circuit Breaker)

What is AC? Alternating Current (AC) is the form of electrical current commonly used in homes, businesses, and industries. It is characterized by the periodic reversal of direction, typically occurring 50 or 60 times per second (50 Hz or 60 Hz), depending on the region. This back-and-forth motion of electrons allows AC to be easily transmitted over long distances and converted to different voltages using transformers.

How AC MCB Works: AC MCBs are designed to handle the unique properties of AC electricity. When an overload or short circuit occurs, the MCB detects the excessive current flow and interrupts the circuit. The AC MCB uses both thermal and magnetic mechanisms to achieve this:

Thermal Mechanism: In the presence of a prolonged overcurrent, a bimetallic strip inside the MCB heats up and bends. This bending action eventually trips the breaker, disconnecting the circuit.

Magnetic Mechanism: For short circuits, the sudden surge in current creates a strong magnetic field that moves a trip lever, instantly breaking the circuit.

Applications of AC MCB: AC MCBs are widely used in various settings, including:

Residential: Protecting household circuits powering lights, outlets, and appliances.

Commercial: Safeguarding electrical systems in offices, retail stores, and other commercial establishments.

Industrial: Ensuring the safety of machinery and equipment in manufacturing plants and industrial facilities.

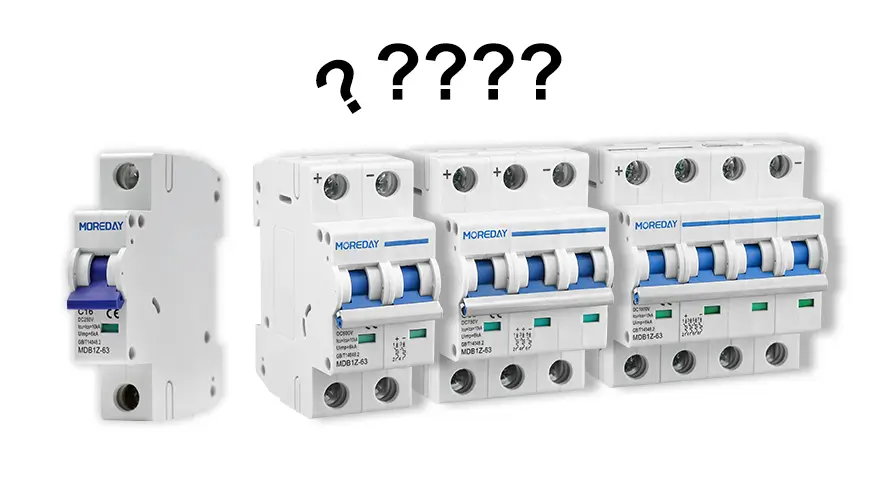

DC MCB (Direct Current Miniature Circuit Breaker)

What is DC? Direct Current (DC) is a type of electrical current where the flow of electric charge is in one constant direction. DC is commonly used in batteries, solar panels, electric vehicles, and certain industrial applications. Unlike AC, DC does not change direction periodically, which affects how circuit breakers designed for DC systems operate.

How DC MCB Works: DC MCBs are engineered to manage the continuous, unidirectional flow of DC electricity. The design of a DC MCB differs from an AC MCB due to the unique challenges posed by DC:

Thermal Mechanism: Similar to AC MCBs, DC MCBs use a bimetallic strip that heats up and bends when there is an overcurrent. This bending trips the breaker and interrupts the circuit.

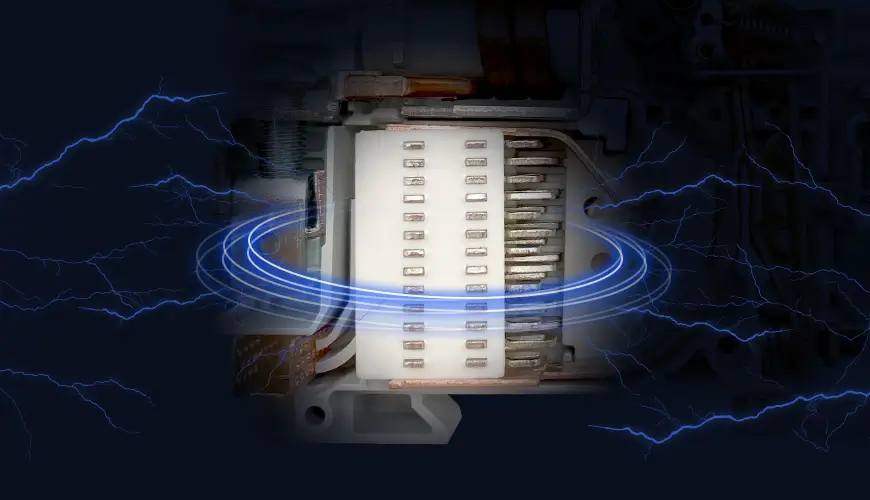

Magnetic Mechanism: DC MCBs also use a magnetic trip mechanism to respond to short circuits. However, extinguishing the arc in DC systems is more challenging because the current does not drop to zero periodically. Therefore, DC MCBs often have more robust arc extinguishing mechanisms, such as magnetic blowout coils, to manage the persistent arc.

Applications of DC MCB: DC MCBs are used in specialized applications where DC power is prevalent, including:

Solar Power Systems: Protecting circuits in photovoltaic (PV) installations.

Electric Vehicles: Ensuring the safety of electrical systems in EVs.

Battery Systems: Safeguarding battery storage systems in various applications.

Industrial Equipment: Used in machinery and control systems that operate on DC power.

Key Differences Between AC MCB and DC MCB

Current Type

Alternating Current (AC): AC MCBs are designed for systems that use alternating current. AC is characterized by the periodic reversal of direction, typically occurring 50 or 60 times per second (Hertz). This alternating nature of the current means that the voltage also oscillates between positive and negative values. This periodic zero-crossing point helps in the easier interruption of the current flow when the MCB trips.

Direct Current (DC): DC MCBs, on the other hand, are designed for systems that use direct current. DC is a constant, unidirectional flow of electric charge. Unlike AC, DC does not have a zero-crossing point, which makes interrupting the current more challenging. The continuous nature of DC current requires MCBs to have specialized mechanisms to effectively break the circuit.

Arc Extinguishing Mechanism

AC Arc Extinguishing: When an AC MCB trips, the alternating nature of the current helps in extinguishing the arc. Since the current passes through zero voltage multiple times per second, the arc naturally diminishes at these points. AC MCBs typically use arc chutes and other mechanisms to cool and divide the arc, facilitating its extinction.

DC Arc Extinguishing: DC MCBs face a more complex challenge in extinguishing arcs because the current is constant and does not naturally pass through zero. As a result, the arc can persist longer and be more intense. DC MCBs often incorporate more robust arc extinguishing methods, such as magnetic blowout coils, which create a magnetic field to stretch and dissipate the arc, or longer arc chambers to elongate and cool the arc more effectively.

Contact Design

AC MCB Contact Design: The contacts in AC MCBs are designed to handle the periodic current flow and the relatively easier arc extinguishing due to the zero-crossing points. These contacts are generally less robust than those in DC MCBs because the arc is less severe.

DC MCB Contact Design: DC MCBs have more robust and durable contact designs to cope with the continuous and more intense arcs in DC circuits. The contacts are often made from materials that can withstand higher temperatures and prolonged exposure to arcs, ensuring reliable interruption of the current.

Voltage Ratings

AC MCB Voltage Ratings: AC MCBs typically have voltage ratings suited for common residential and commercial applications, which usually range from 110V to 240V, depending on the region. Industrial AC MCBs can handle higher voltages but are generally designed for standard AC system voltages.

DC MCB Voltage Ratings: DC MCBs usually have higher voltage ratings to accommodate the steady and potentially higher energy levels in DC systems. These ratings can range from low voltage applications (e.g., 12V or 24V in battery systems) to high voltage applications (e.g., 600V or more in solar power installations).

Application Environment

AC MCB Usage Scenarios: AC MCBs are widely used in residential, commercial, and general industrial settings where AC power is prevalent. Common applications include:

Residential: Protecting household circuits that power lights, outlets, and appliances.

Commercial: Ensuring the safety of electrical systems in offices, retail stores, and other commercial buildings.

Industrial: Safeguarding machinery and equipment in manufacturing plants and general industrial facilities.

DC MCB Usage Scenarios: DC MCBs are used in specialized applications where DC power is predominant. These applications include:

Solar Power Systems: Protecting circuits in photovoltaic (PV) installations, which generate DC electricity.

Electric Vehicles: Ensuring the safety of electrical systems in electric vehicles, which rely on DC power from batteries.

Battery Systems: Safeguarding battery storage systems used in various applications, including backup power supplies and renewable energy storage.

Industrial Equipment: Protecting machinery and control systems that operate on DC power in specialized industrial settings.

Common Misconceptions

When it comes to Miniature Circuit Breakers (MCBs), there are several misconceptions that can lead to confusion and potentially unsafe practices. Understanding these misconceptions is vital for making informed decisions about electrical protection. Here, we address some of the most common misunderstandings about AC MCBs and DC MCBs.

Misunderstandings About AC MCBs

Misconception 1: AC MCBs Can Be Used in DC Circuits

One of the most prevalent misconceptions is that AC MCBs can be used interchangeably in DC circuits. This is incorrect and potentially dangerous. AC MCBs are specifically designed to handle the properties of alternating current, including the natural zero-crossing points that assist in extinguishing arcs. In DC circuits, where the current flow is constant and unidirectional, the lack of zero-crossing points makes arc extinguishing more challenging. Using an AC MCB in a DC circuit can lead to prolonged arcing, increased heat, and potential fire hazards.

Misconception 2: AC MCBs Are Inferior to DC MCBs

Some people believe that DC MCBs are superior to AC MCBs in all aspects. This is not true. AC MCBs are perfectly suited for their intended applications. They are designed to protect circuits that use alternating current, which is the standard in residential, commercial, and many industrial environments. AC MCBs are not inferior; they are simply different, with designs tailored to the characteristics of AC power.

Misconception 3: Higher Amperage Ratings Are Always Better

Another common misunderstanding is that selecting an MCB with a higher amperage rating than needed is always a good idea. This can lead to insufficient protection. An MCB with a higher rating may not trip when there is an overload or short circuit, potentially causing damage to the wiring and connected devices. It is crucial to select an MCB with the appropriate rating for the specific circuit to ensure proper protection.

Misunderstandings About DC MCBs

Misconception 1: DC MCBs Are Unnecessary in Modern Electrical Systems

Some people think that because most electrical systems use AC power, DC MCBs are unnecessary. However, with the increasing use of renewable energy sources like solar panels, and the growing popularity of electric vehicles, the demand for DC MCBs is rising. These applications require specialized protection that only DC MCBs can provide, making them essential for modern electrical systems that incorporate DC power.

Misconception 2: All DC MCBs Are the Same

Another common misconception is that all DC MCBs are identical. In reality, DC MCBs vary significantly in their design and specifications based on their intended application. For instance, DC MCBs used in solar power systems might differ from those used in electric vehicles or industrial equipment. It’s important to choose a DC MCB that matches the specific requirements of the application, considering factors like voltage rating, current rating, and environmental conditions.

Misconception 3: DC MCBs Can Be Used in AC Circuits

Just as AC MCBs are not suitable for DC circuits, the reverse is also true. DC MCBs are designed to handle the unique challenges of direct current, such as persistent arcing. Using a DC MCB in an AC circuit can result in inefficient arc extinguishing and inadequate protection, as the device is not optimized for the alternating nature of AC power. This can compromise the safety and functionality of the electrical system.

Conclusion

Choosing the right MCB is not merely a matter of preference but a critical decision that impacts the safety, efficiency, and longevity of your electrical systems. The distinctions between AC MCBs and DC MCBs highlight the importance of selecting the correct device based on the type of current and specific application requirements.

For residential and commercial environments where AC power is prevalent, AC MCBs offer reliable protection with simpler installation and maintenance. In contrast, for renewable energy systems, electric vehicles, and other DC applications, DC MCBs provide the necessary robustness and reliability to handle the unique challenges posed by direct current.

As electrical systems continue to evolve with advancements in technology and the growing emphasis on renewable energy, the demand for specialized MCBs will increase. Staying informed about the capabilities and appropriate uses of AC and DC MCBs ensures that your electrical installations are not only compliant with safety standards but also optimized for performance and efficiency.

FAQ`s.

What is the main function of an MCB?

An MCB automatically interrupts electrical flow during overload or short circuit conditions to protect the circuit and connected devices.

Can AC MCB be used in DC circuits?

No, AC MCBs are not suitable for DC circuits due to the different arc extinguishing requirements.

Why is arc extinguishing different in AC and DC MCBs?

AC current naturally drops to zero periodically, making arc extinguishing easier, while DC current is constant, requiring more robust mechanisms.

How to choose between AC and DC MCB for a specific application?

Consider the type of current in your system and choose the MCB designed for that current type—AC for alternating current systems and DC for direct current systems.

Are there MCBs that can handle both AC and DC?

Some specialized MCBs can handle both types of currents, but they are typically designed for specific hybrid applications and should be chosen with care.

Derek Ke

Hi, I’m Derek Ke, founder of Moreday.com, an expert in solar-protected electrical products and electric vehicle charging.

Over the past 15 years, we have helped nearly 500 customers (such as farms, residential, industrial, and commercial) in 60 countries solve new energy and green power problems. We aim to share more knowledge about solar power generation and new energy with everyone so that green electricity can enter thousands of households.