- HOME

- PRODUCTS

- SERVICES

- ABOUT MOREDAY

- NEWS

- CONTACT MOREDAYOur Contacts

We are Here

Malujiao Industrial Park, Beibaixiang Town, Yueqing City, Zhejiang, China 325603

our contacts

info@moreday.com

+86 18106780877Get in TouchYour email address will not be published. Required fields are marked *

Home » Combiner Box

Combiner Box

Combiner Box Manufacturer

Combiner box is an electrical enclosure used to combine, house, and organize solar panel strings. Its function is to consolidate multiple solar panel strings into a single power source before feeding it into an inverter. A solar panel string refers to a series connection of solar panels. Proper placement of the combiner box in a solar photovoltaic system helps reduce energy losses.

Combiner box is needed when more than three solar panel strings need to be connected to the inverter. If there are fewer than three strings, they can be connected directly to the inverter without additional equipment. Large photovoltaic power plants can benefit significantly from combiner boxes, as they help PV plant designers reduce material and labor costs by distributing and combining connections without compromising maximum power output.

When properly installed and of good quality, combiner boxes require virtually no maintenance. The combiner box should meet the technical requirements of your solar project and comply with the CE EN IEC 62619:2022 standard, which is the relevant standard for this type of equipment. While maintenance is unlikely to be needed, it is still recommended to periodically inspect the combiner box to ensure its proper functioning. A poor-quality or faulty combiner box can malfunction or even cause a fire, resulting in serious damage to your photovoltaic system. When using DC and AC components in a solar combiner box installation, they must be kept separate to ensure safety.

Submit your inquiry and we will contact you

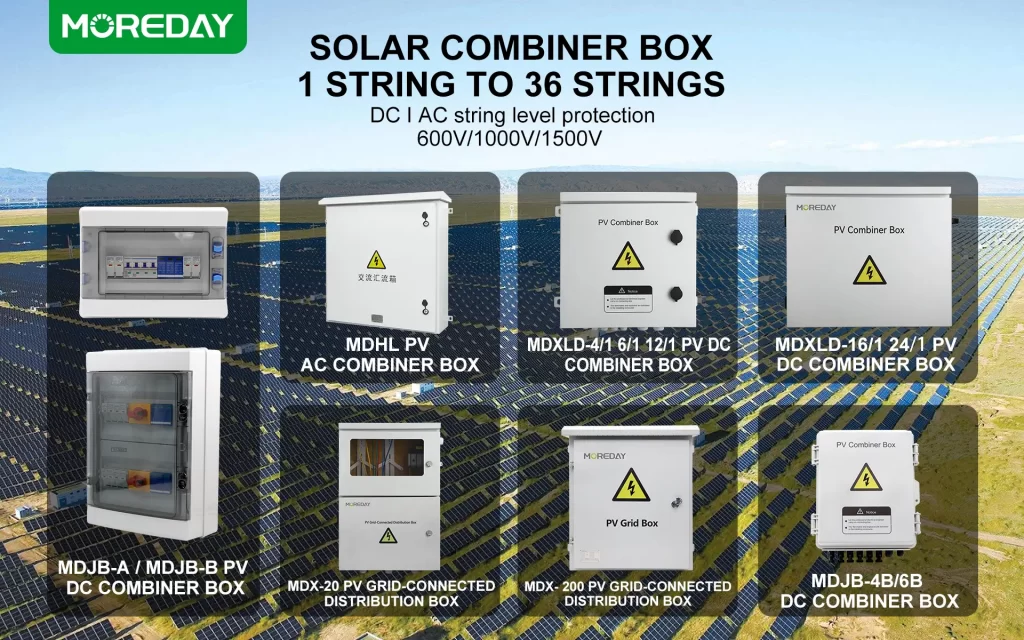

MOREDAY COMBINER BOX PRODUCT SERIES

Solar Combiner Box

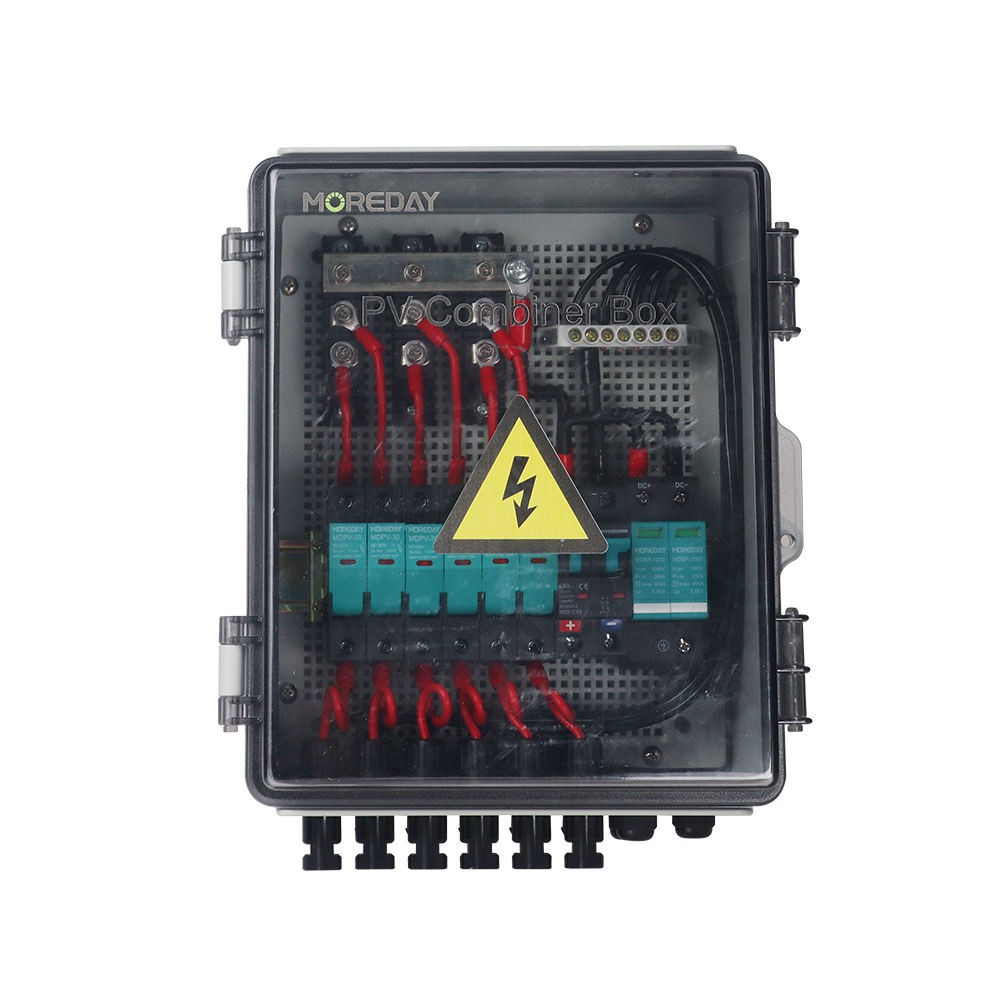

MOREDAY specializes in customized solar combiner boxes, providing superior rooftop fire protection for residential, commercial, and industrial buildings, as well as ground-mounted power plants. Solar DC combiner boxes connect photovoltaic inverters and solar arrays, aggregating the output of multiple series-connected modules to improve the performance of the photovoltaic system. Our unique combiner box design allows for easy integration of additional features, such as switches and a second Maximum Power Point Tracker (MPPT).

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

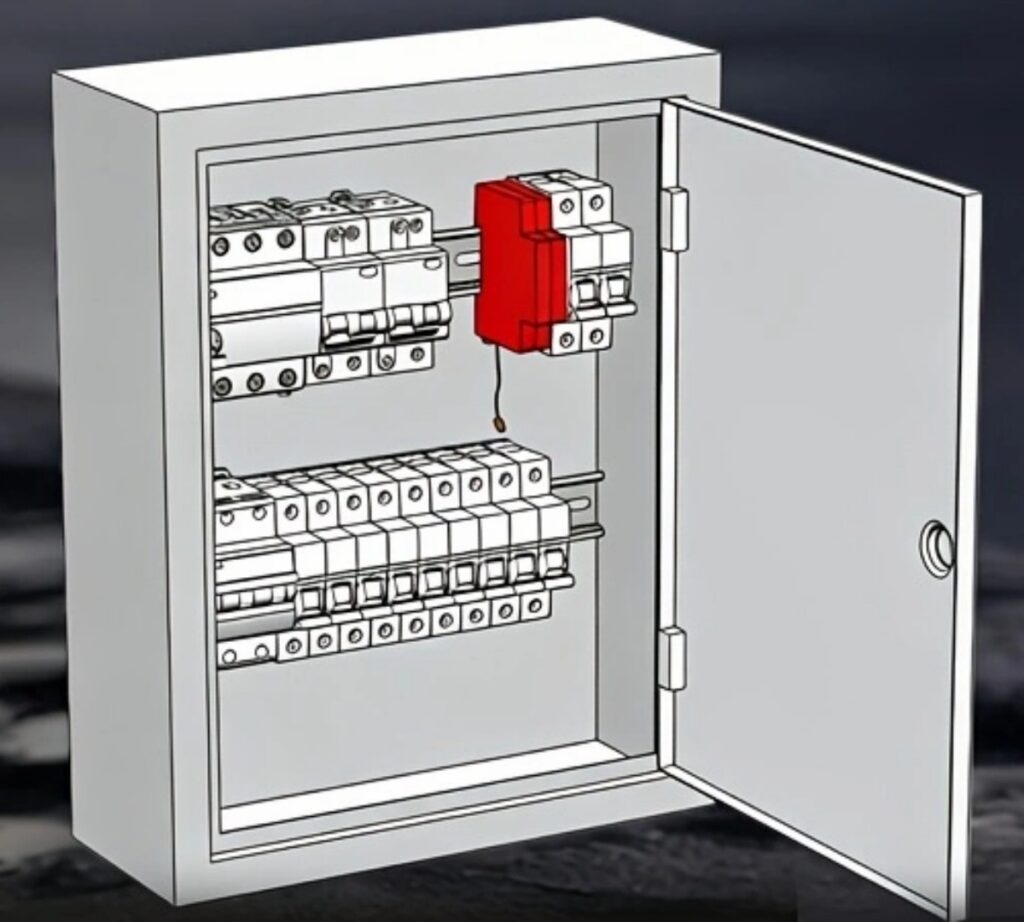

MCB Combiner Box Series

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

AC Combiner Box Series

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

Industrial Combiner Box MDHL Series

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

- IP65

- 600V/800V/1000V/1200V

- Input: 1 to 6 strings

- Output: 1 to 6 strings

- Input current of each string: 15A to 30A

- Output current: 16A to 63A

- Lockable at off position

- Fuses for over-current protection

FAQs

What is a solar combiner box?

A solar combiner box is a device used to collect, organize, and house solar panel strings. It receives the output from multiple solar photovoltaic panels and combines them into a single circuit before sending the power to the inverter. Solar combiner boxes are designed for either AC or DC power, but not both simultaneously. The box contains fuse terminals. The solar panel strings are connected to these terminals, and their output is then transmitted through a single cable to the inverter box.

How does a solar combiner box work?

A solar panel combiner box brings together the outputs of all the strings (or inverters). The output current from these strings is fed into the combiner box, converting the power into a single circuit. The single wire output from the combiner box can then be connected to your inverter or main load center.

Why do you need a solar combiner box?

Complex solar panel arrays require careful organization so that engineers can quickly install and maintain the system and minimize energy loss. Combiner boxes are a cost-effective solution for connecting solar panel strings to the inverter. Without a solar combiner box, engineers would have to connect multiple strings directly to the inverter, which could lead to tangled and disorganized wiring, and even pose safety hazards.

Combiner boxes also prevent excessive current from entering the inverter. They can quickly shut down the system in the event of a voltage surge, acting as a rapid remote disconnect switch. This also helps save costs by reducing maintenance requirements and lowering the risk of damaging the inverter.

Is a Solar Combiner Box Necessary?

Typically, only three or fewer strings of solar panels are used – otherwise, using a solar combiner box offers many advantages. While you might not want to add extra costs to an already expensive system, a solar combiner box is definitely worth the investment. Most combiner boxes are affordable and will save you money in the long run.

First, without a solar combiner box, many wires would be directly connected to the inverter. Using a combiner box reduces the number of wires, thus reducing hassle. You save on materials and installation costs because you don’t need to buy as many wires. A solar combiner box also shortens installation time.

A solar combiner box reduces energy loss on the AC side. It also shortens the length of wiring between the inverter and transformer. Besides saving on materials, you can utilize the collected energy more efficiently.

Connecting too many wires to a solar inverter can cause problems. A solar combiner box helps you avoid excessive wire connections.

If a problem occurs, it’s easier to locate the fault. If a fault occurs, you can more easily identify which wire is causing the problem and fix it. Because all cables are consolidated in one location, a solar combiner box also makes maintenance more convenient.

A solar combiner box can also serve as an extra safety measure for the system. You can choose combiner boxes with additional components, such as surge protection devices, string monitoring software, and more.

Since all wires are connected to the solar combiner box, the entire system can be easily shut down in case of a power surge. You can prevent power surges from entering the inverter. You can even add a remote rapid shutdown function for any emergencies.

Considering future strategies, I recommend purchasing a solar combiner box. MOREDAY manufactures ABS+PC and metal solar combiner boxes, supporting 1 to 36 string, which can effectively help you improve efficiency.

What are the parts of a solar combiner box?

A solar combiner box is made of several simple but important parts.

Here are the main ones, explained clearly:

- DC input terminals

These are where the positive (+) and negative (−) cables from solar panels are connected. - DC fuses

Each solar string has a fuse.

They protect the system if too much current flows. - DC circuit breaker or DC isolator switch

This allows the system to be safely turned off for maintenance or emergencies. - Surge protection device (SPD)

This protects the system from lightning or voltage spikes. - Busbars (positive and negative)

These combine the power from all solar strings into one output. - DC output terminals

This is where the combined power goes out to the inverter. - Grounding (earthing) terminal

This connects the box to earth for safety. - Enclosure (box housing)

The outer box that protects all parts from dust, moisture, and damage.

Types of Combiner Boxes

- DC Combiner Box

Used in solar PV systems

Combines several solar panel strings into one DC output

Connects to the inverter

- AC Combiner Box

Used on the AC side of the system

Combines outputs from multiple inverters

Connects to the grid or main distribution board

- PV String Combiner Box

Designed for string inverters

Usually supports multiple DC inputs (such as 6, 9, or more strings)

Common in rooftop and small commercial systems

- Main Combiner Box (Array Combiner Box)

Used in large solar plants

Combines many smaller combiner boxes into one larger output

Sends power to central inverters

- Smart Combiner Box

Includes monitoring functions

Can measure current, voltage, and temperature

Helps detect faults early

- Standard Combiner Box

Basic protection only

Includes fuses, surge protection, and a switch

No monitoring features

Installation and Maintenance

Proper installation and regular maintenance of a solar combiner box are essential to ensure system safety, stable performance, and long service life.

- Installation

The combiner box should be installed in a suitable location that is easy to access for wiring and future maintenance. Clear labeling and a reasonable internal layout help reduce installation time and minimize wiring mistakes, which can also lower labor costs. - Wiring

All wiring must be done correctly and securely. Loose or incorrect connections may cause overheating, power loss, or electrical shock. Always follow the manufacturer’s wiring instructions and ensure that cable sizes and terminals match the system requirements. - Breakers and Protection Devices

The combiner box should be equipped with properly rated DC fuses, circuit breakers, or isolator switches that are compatible with the solar system. These components protect the system from overcurrent, short circuits, and other electrical faults. - String Monitoring (if applicable)

Combiner boxes with string monitoring can track the current or voltage of each PV string. This makes it easier to detect abnormal performance, identify faulty strings, and maintain overall system efficiency. - Maintenance

Regular inspections are recommended. Check for loose connections, damaged cables, corrosion, or signs of overheating. Keeping the combiner box clean and dry helps maintain reliable operation and reduces the risk of failure.

By following correct installation practices and performing routine maintenance, the combiner box can operate safely and reliably, helping the solar power system run efficiently over the long term.

Fire & Electrical Safety Enhancements for Combiner Boxes

High-density solar power generation systems also come with high risks, combiner boxes play a key role in both power distribution and system safety. In addition to basic electrical protection components like breakers and surge protection devices, fire risk mitigation inside combiner boxes is an important consideration, especially where multiple strings and high DC current converge.

Why Internal Fire Safety Matters

The concentrated DC current from multiple PV strings, if unmanaged or subject to fault conditions like arcs or loose connections, can increase heat accumulation and the potential for ignition in enclosed spaces. Early detection and suppression mechanisms help reduce fire escalation and protect downstream equipment.

Integrated Fire Suppression Solutions

One effective approach is integrating fire suppression devices suited for electrical enclosures, such as aerosol fire suppression systems. These systems are designed to work within compact electrical enclosures — releasing fine aerosol agents that interrupt combustion without damaging electrical components or leaving conductive residue. When triggered by heat or fault conditions, they can suppress fire at the source rapidly and automatically, enhancing safety in critical DC distribution points.

Integrating such safety enhancements into combiner box design or adjacent enclosures can improve overall system reliability and reduce the risk of electrical fires — particularly in large-scale or unattended installations where early intervention is crucial.

Compared with portable fire extinguishers, aerosol fire suppression systems are better suited for enclosed electrical environments.

Ask for Free Quote Now

We can provide Free Standard samples for you to check the quality and printing options.