In the world of electrical systems, choosing the right components is crucial for safety and efficiency. One such component is the Miniature Circuit Breaker (MCB), which plays a vital role in protecting electrical circuits from overloads and short circuits. However, a common question that arises is whether a DC MCB can be used for AC applications. This article will explore the differences between DC and AC MCBs, their specific uses, and address the question at hand.

M

iniature Circuit Breakers are automatic electrical switches designed to protect electrical circuits from damage caused by excess current from overloads or short circuits. They are essential components in both residential and industrial electrical systems. However, not all MCBs are created equal, and it’s crucial to understand the differences between those designed for DC (Direct Current) and AC (Alternating Current) applications.

Understanding DC MCBs

DC MCBs (Miniature Circuit Breakers) are specialized protective devices designed specifically for use in Direct Current (DC) electrical systems. These devices play a crucial role in ensuring the safety and reliability of DC circuits. Let’s explore various aspects of DC MCBs in detail:

Definition and Function

DC MCBs are automatic electrical switches that protect DC circuits from overcurrent situations, including overloads and short circuits. Their primary functions include:

a) Circuit Protection: Interrupting the flow of current when it exceeds safe levels.

b) Isolation: Providing a means to manually disconnect the circuit for maintenance or emergencies.

c) Resettability: Allowing the circuit to be restored after addressing the fault condition.

Key Features of DC MCBs

a) Wider Contact Gaps: As previously discussed, DC MCBs have wider contact gaps to effectively extinguish DC arcs.

b) Specialized Arc Chutes: These are designed to quickly cool and dissipate the energy of DC arcs:

Multiple metal plates to divide and cool the arc

Refractory materials to withstand high temperatures

Optimized geometry for efficient arc movement and extinction

c) Higher Voltage Ratings: DC MCBs typically have higher voltage ratings compared to AC MCBs of similar size due to the challenges of interrupting DC current.

d) Polarized Connections: Many DC MCBs are polarized, meaning they have specific terminals for positive and negative connections to ensure proper operation.

e) Magnetic Blowout Mechanism: Some DC MCBs incorporate magnetic blowout coils to help extinguish the arc more quickly:

These coils create a magnetic field that pushes the arc into the arc chute

The magnetic field also helps to stretch and cool the arc

f) Trip Mechanisms: DC MCBs use both thermal and magnetic trip mechanisms:

Thermal trips protect against prolonged overloads

Magnetic trips provide fast response to short circuits

g) DC-specific Trip Curves: The trip characteristics are tailored to DC loads, which can have different inrush and steady-state current profiles compared to AC loads.

Operating Principles

a) Normal Operation: Under normal conditions, the MCB allows current to flow through its contacts with minimal resistance.

b) Overload Detection: During an overload, the bimetallic strip in the thermal trip mechanism heats up and bends, eventually triggering the tripping mechanism.

c) Short Circuit Detection: In case of a short circuit, the magnetic trip mechanism reacts almost instantly to the high current, activating the tripping mechanism.

d) Arc Interruption: When the contacts open, an arc forms. The DC MCB uses its specialized features (wide gaps, arc chutes, magnetic blowout) to quickly extinguish this arc.

e) Lockout: After tripping, the MCB remains in the open position until manually reset, preventing automatic reconnection to a faulted circuit.

Common Applications

DC MCBs find use in various applications, including:

a) Solar Power Systems: Protecting DC circuits in photovoltaic installations.

b) Electric Vehicle Charging Stations: Safeguarding DC fast-charging equipment.

c) Telecommunications: Protecting DC-powered communication systems and backup power supplies.

d) Industrial Control Systems: Providing protection in DC control circuits and motor drives.

e) Battery-based Power Systems: Protecting circuits in uninterruptible power supplies (UPS) and energy storage systems.

f) Railway Systems: Safeguarding DC traction power and auxiliary circuits in trains and trams.

g) Marine Applications: Protecting DC circuits in ships and offshore platforms.

AC MCBs: A Comparison

AC MCBs (Alternating Current Miniature Circuit Breakers) are designed specifically for use in alternating current electrical systems. While they serve a similar protective function as DC MCBs, their design and operation differ significantly due to the unique characteristics of AC power. Let’s explore AC MCBs in detail and compare them to their DC counterparts:

Definition and Function of AC MCBs

AC MCBs are automatic electrical switches designed to protect AC circuits from overcurrent conditions, including overloads and short circuits. Their primary functions include:

a) Overcurrent Protection: Interrupting excessive current flow to prevent damage to wiring and connected equipment.

b) Short Circuit Protection: Rapidly disconnecting the circuit in case of a short circuit to prevent electrical fires and equipment damage.

c) Manual Disconnection: Providing a means to manually disconnect the circuit for maintenance or emergencies.

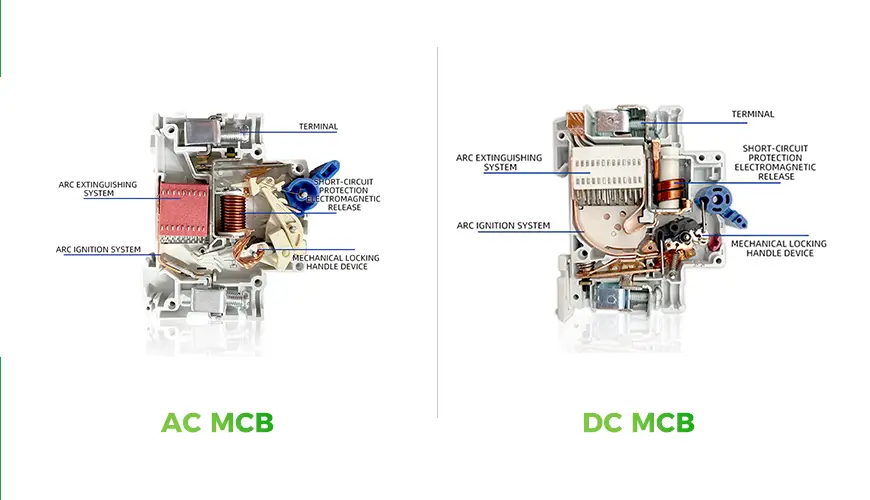

Key Differences between DC and AC MCBs

a) Arc Interruption:

AC MCBs: Take advantage of the natural zero-crossing point of AC waveforms to extinguish arcs. This occurs twice per cycle (100 times per second in 50Hz systems, 120 times per second in 60Hz systems), making arc extinction easier.

DC MCBs: Require more robust arc suppression mechanisms due to the continuous nature of DC current, including wider contact gaps and specialized arc chutes.

b) Contact Design:

AC MCBs: Typically have smaller contact gaps compared to DC MCBs, as the arc is easier to extinguish in AC systems.

DC MCBs: Require wider contact gaps to effectively stretch and cool the DC arc.

c) Magnetic Trip Mechanism:

AC MCBs: Often use simpler magnetic trip mechanisms due to the alternating nature of the current, which produces a varying magnetic field that aids in tripping.

DC MCBs: May require more complex magnetic trip mechanisms to achieve rapid tripping in DC circuits.

d) Voltage Ratings:

AC MCBs: Generally have lower voltage ratings compared to DC MCBs of similar size, due to the easier arc extinction in AC systems.

DC MCBs: Typically rated for higher voltages to handle the challenges of DC arc interruption.

e) Polarity Sensitivity:

AC MCBs: Not polarity sensitive, as AC current alternates direction.

DC MCBs: Often polarity sensitive, with specific terminals for positive and negative connections.

Applications

AC MCBs are used in a wide range of applications, including:

Residential electrical systems

Commercial and industrial power distribution

Motor protection

Lighting circuits

HVAC systems

General-purpose power outlets

Can DC MCBs be used for AC circuits?

The short answer remains no, DC MCBs should not be used for AC circuits. Let’s examine this in more detail:

Technical Considerations

a) Fundamental Design Differences:

DC MCBs are specifically engineered to handle the unique characteristics of direct current, which flows consistently in one direction.

AC current alternates direction multiple times per second (50 or 60 times in most power systems), which requires different design considerations.

b) Arc Interruption Mechanisms:

DC MCBs rely on elongating and cooling the arc to extinguish it, using wider contact gaps and specialized arc chutes.

AC MCBs take advantage of the natural zero-crossing points in the AC waveform to extinguish arcs, which occur 100 or 120 times per second in 50Hz or 60Hz systems, respectively.

c) Magnetic Trip Characteristics:

The magnetic trip mechanism in DC MCBs is designed for constant, unidirectional current flow.

AC magnetic trip mechanisms are optimized for the oscillating magnetic fields produced by alternating current.

d) Contact Design:

DC MCB contacts are designed to withstand the constant electromagnetic forces of DC current.

AC MCB contacts are engineered to handle the cyclical forces of alternating current.

Potential Risks and Limitations

a) Reduced Breaking Capacity:

DC MCBs used in AC circuits may not be able to interrupt fault currents effectively, potentially leading to sustained arcing and equipment damage.

b) Failure to Interrupt AC Faults:

The arc extinction method used in DC MCBs is not optimized for AC arcs, which could result in the MCB failing to clear a fault condition.

c) Increased Wear and Tear:

Using a DC MCB in an AC circuit can lead to accelerated wear of the contacts and internal mechanisms, shortening the device’s lifespan.

d) Nuisance Tripping or Failure to Trip:

The trip characteristics of DC MCBs are not calibrated for AC loads, which could result in either unnecessary tripping or failure to trip when required.

e) Thermal Management Issues:

DC MCBs may not effectively manage the heat generated by AC current, potentially leading to overheating and premature failure.

f) Improper Response to Inrush Currents:

Many AC loads have high inrush currents (e.g., motors, transformers). DC MCBs are not designed to handle these transient currents properly.

Conclusion

In conclusion, while DC MCBs and AC MCBs may appear similar, they are designed for fundamentally different types of electrical systems. The use of DC MCBs in AC circuits, or AC MCBs in DC circuits, is not just inadvisable—it’s dangerous and potentially illegal. Ensuring the correct selection and application of MCBs is crucial for the safety, reliability, and efficiency of any electrical system.

As electrical systems continue to evolve and become more complex, particularly with the integration of renewable energy sources and smart grid technologies, the importance of understanding and correctly applying circuit protection devices like MCBs becomes even more critical. It is the responsibility of everyone involved in electrical systems—from designers and installers to end-users and maintenance personnel—to ensure that the right protection devices are used in the right applications.

By adhering to these principles and always choosing the appropriate MCB for each specific application, we can maintain the highest standards of electrical safety and system reliability, protecting both people and equipment from the potential dangers of electrical faults.

Ensure the safety and reliability of your DC electrical systems with high-quality DC MCBs. MOREDAY, a professional and reliable DC circuit breaker manufacturer, offers a wide range of DC MCBs designed to meet the highest standards of performance and safety. Protect your valuable equipment and ensure uninterrupted operation by choosing MOREDAY DC MCBs for your DC applications. Visit our website or contact our sales team today to learn more about our products and find the perfect DC MCB solution for your needs. Don’t compromise on safety – choose MOREDAY for all your DC circuit protection requirements.

FAQ`s.

Q1: Can I use an AC MCB in a DC circuit?

A1: No, AC MCBs are not designed to handle DC power and should not be used in DC circuits. The arc interruption mechanism in AC MCBs relies on the zero-crossing point of AC waveforms, which doesn't exist in DC circuits. Using an AC MCB in a DC circuit could result in failure to interrupt faults and potential safety hazards.

Q2: How can I identify whether an MCB is for DC or AC use?

A2: MCBs are typically clearly labeled with their intended use (DC or AC) and rated voltage. Look for markings on the MCB body or in the accompanying documentation. DC MCBs often have a symbol showing a straight line with dashes, while AC MCBs have a wavy line symbol.

Q3: Are there universal MCBs that work for both DC and AC?

A3: Some manufacturers produce hybrid MCBs designed for both DC and AC applications. However, these are specialized products and not as common as dedicated DC or AC MCBs. Always check the manufacturer's specifications to ensure the MCB is rated for your specific application.

Q4: What happens if I accidentally use a DC MCB in an AC circuit?

A4: Using a DC MCB in an AC circuit can lead to reduced protection, potential failure to trip during faults, and increased wear on the device. It's a safety hazard that could result in equipment damage or electrical fires. If you've accidentally installed a DC MCB in an AC circuit, replace it immediately with an appropriate AC MCB.

Q5: Do DC MCBs have different trip curves like AC MCBs (B, C, D curves)?

A5: Yes, DC MCBs can have different trip curves, though they might not be labeled in the same way as AC MCBs. The trip characteristics are tailored to DC loads, which can have different inrush and steady-state current profiles compared to AC loads.

Derek Ke

Hi, I’m Derek Ke, founder of Moreday.com, an expert in solar-protected electrical products and electric vehicle charging.

Over the past 15 years, we have helped nearly 500 customers (such as farms, residential, industrial, and commercial) in 60 countries solve new energy and green power problems. We aim to share more knowledge about solar power generation and new energy with everyone so that green electricity can enter thousands of households.