WHAT IS DC AND AC ISOLATOR SWITCH?

Introduction

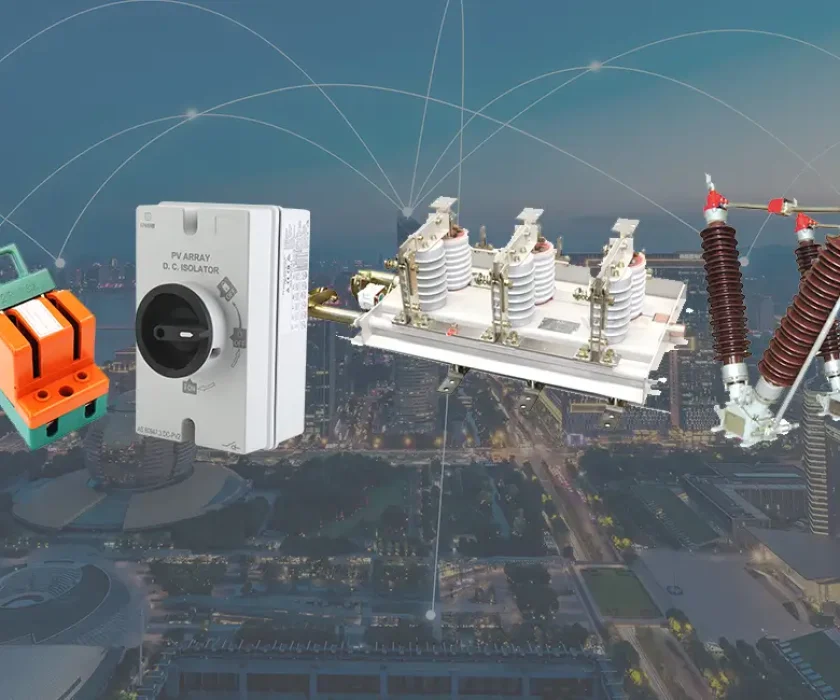

Isolator switches, also known as disconnect switches or isolators, are fundamental components in electrical systems used to isolate circuits or equipment for maintenance, repair, or emergency shutdowns. They serve as a crucial safety mechanism, providing a physical barrier to the flow of electrical current, thereby preventing accidents, injuries, or damage to equipment.

In essence, isolator switches act as a manual means of disconnecting power sources from loads, effectively breaking the electrical connection to ensure the safety of personnel working on the system. Unlike circuit breakers, which automatically trip in response to overcurrent or short circuits, isolator switches require manual operation, providing users with direct control over the power flow.

In addition to their primary function of isolating electrical circuits, isolator switches may also feature additional capabilities such as lockout/tagout mechanisms to prevent accidental activation, padlock provisions for securing the switch in the off position, and remote operation for enhanced convenience and control.

Understanding DC Isolator Switches

Importance in DC Electrical Systems

In the realm of direct current (DC) electrical systems, such as those found in solar photovoltaic (PV) installations, battery storage systems, and DC-powered machinery, isolator switches play a paramount role in ensuring safety and facilitating maintenance procedures.

DC isolator switches serve as crucial components for the safe operation and maintenance of DC circuits. They provide a means to disconnect DC power sources from loads, allowing for isolation during maintenance, repair, or emergency situations. This capability is especially vital in solar PV installations, where DC power generated by solar panels needs to be safely managed and isolated when necessary.

Components and Functionality

DC isolator switches typically consist of robust construction housed within durable enclosures designed to withstand environmental conditions. Within these enclosures, a switch mechanism allows for manual control of the electrical circuit. When the switch is in the “on” position, it allows the flow of DC current through the circuit, enabling the operation of connected devices or systems. Conversely, when switched off, the isolator switch physically breaks the connection, preventing the flow of DC power and effectively isolating the circuit.

The design and construction of DC isolator switches prioritize safety and reliability. They are engineered to handle the specific characteristics of DC power, including voltage levels and current ratings, ensuring optimal performance and longevity in DC electrical systems.

Furthermore, DC isolator switches may incorporate features such as arc suppression technology to mitigate the risk of arcing during switching operations, enhancing safety and minimizing the potential for electrical hazards.

Understanding AC Isolator Switches

Importance in AC Electrical Systems

In the realm of alternating current (AC) electrical systems, AC isolator switches play a pivotal role in ensuring safety and facilitating maintenance procedures. These switches provide a means to disconnect AC power sources from loads, enabling isolation during maintenance, repair, or emergency situations.

AC isolator switches are indispensable components in residential, commercial, and industrial electrical systems, where they are utilized to disconnect power to appliances, machinery, or entire circuits. Whether it’s a simple light switch or a more complex industrial application, AC isolator switches provide a crucial safety mechanism for controlling the flow of AC current.

Components and Functionality

Similar to their DC counterparts, AC isolator switches consist of robust construction housed within durable enclosures designed to withstand environmental conditions. Within these enclosures, a switch mechanism allows for manual control of the electrical circuit.

When the switch is in the “on” position, it permits the flow of AC current through the circuit, enabling the operation of connected devices or systems. Conversely, when switched off, the isolator switch physically breaks the connection, preventing the flow of AC power and effectively isolating the circuit.

AC isolator switches are designed to handle the specific characteristics of AC power, including voltage levels, frequency, and current ratings. They are engineered for reliable performance and longevity in AC electrical systems, with features such as arc suppression technology to mitigate the risk of arcing during switching operations.

Furthermore, AC isolator switches may incorporate additional safety features such as interlocking mechanisms to prevent accidental activation and padlock provisions for securing the switch in the off position, enhancing safety and control.

Key Differences Between DC and AC Isolator Switches

When comparing DC and AC isolator switches, several key differences exist in their design, functionality, and applications. Understanding these distinctions is essential for selecting the appropriate switch for a specific electrical system or application.

1. Current Type:

The primary difference between DC and AC isolator switches lies in the type of current they handle. DC isolator switches are specifically designed to handle direct current, which flows continuously in one direction. In contrast, AC isolator switches are tailored for alternating current, where the flow of electricity periodically reverses direction.

2. Voltage and Current Ratings:

DC and AC isolator switches may have different voltage and current ratings to accommodate the specific requirements of DC or AC electrical systems. DC isolator switches are rated for the voltage and current levels typically associated with DC power sources, such as solar panels or battery banks. Similarly, AC isolator switches are rated for the voltage and current levels of AC power distribution systems.

3. Construction and Components:

While both DC and AC isolator switches share similarities in their basic design and functionality, there may be differences in their construction and internal components. DC isolator switches may incorporate features tailored to the unique characteristics of DC power, such as arc suppression technology optimized for DC circuits. Similarly, AC isolator switches may include components designed to handle the periodic fluctuations in AC current.

4. Applications:

DC and AC isolator switches are utilized in different applications based on the type of electrical system they are designed for. DC isolator switches are commonly used in DC-powered systems such as solar PV installations, battery storage systems, and automotive applications. AC isolator switches, on the other hand, find widespread use in residential, commercial, and industrial AC electrical systems for disconnecting power to appliances, machinery, or entire circuits.

Applications of DC Isolator Switches

DC isolator switches are versatile components that find widespread use in various applications where direct current (DC) power sources are utilized. Their primary function is to provide a means of isolating DC power sources from loads for maintenance, repair, or emergency shutdowns. Let’s explore some of the key applications where DC isolator switches are commonly employed:

1. Solar Photovoltaic (PV) Installations:

One of the most prominent applications of DC isolator switches is in solar PV systems. These switches are installed between the solar panels and the inverter to isolate the DC circuit during maintenance, installation, or emergency situations. DC isolator switches play a crucial role in ensuring the safety and proper functioning of solar PV installations by providing a means to disconnect the solar panels from the rest of the system.

2. Battery Storage Systems:

DC isolator switches are integral components of battery storage systems, where they are used to isolate the battery bank from the rest of the electrical system. This allows for safe maintenance procedures and prevents the risk of electrical hazards when working on the battery system. DC isolator switches ensure the efficient and reliable operation of battery storage systems by providing a reliable means of disconnecting the DC power source.

3. Automotive and Marine Applications:

In automotive and marine applications, DC isolator switches are utilized to isolate batteries, electrical systems, and onboard equipment. These switches allow for the safe disconnection of power sources during maintenance or in case of emergencies. DC isolator switches play a critical role in ensuring the safety and reliability of electrical systems in vehicles, boats, and other mobile applications.

4. Telecommunications and Data Centers:

DC isolator switches are also used in telecommunications infrastructure and data centers to isolate DC power sources and equipment. They provide a means to disconnect power to servers, networking equipment, and other critical components for maintenance or repair purposes. DC isolator switches help ensure the uptime and reliability of telecommunications networks and data center operations.

5. Industrial and Commercial Applications:

In industrial and commercial settings, DC isolator switches are employed in various DC-powered systems and equipment. These may include DC motor controls, industrial machinery, and power distribution systems. DC isolator switches allow for safe isolation of DC power sources during maintenance activities, ensuring the safety of personnel and equipment.

Applications of AC Isolator Switches

AC isolator switches are versatile components that play a vital role in ensuring the safety and functionality of alternating current (AC) electrical systems. These switches are utilized in a wide range of applications across residential, commercial, and industrial settings. Let’s explore some of the key applications where AC isolator switches are commonly employed:

1. Residential Electrical Systems:

In residential settings, AC isolator switches are commonly used to disconnect power to individual circuits or appliances for maintenance or repair. They are installed in electrical panels or junction boxes to provide a convenient means of isolating power sources when needed. AC isolator switches ensure the safety of homeowners and electricians by allowing for the safe handling of electrical systems.

2. Commercial Buildings and Offices:

In commercial buildings, offices, and retail spaces, AC isolator switches are employed to disconnect power to lighting circuits, HVAC systems, and other electrical equipment. They are essential for facilitating maintenance procedures and ensuring the safety of occupants and maintenance personnel. AC isolator switches provide a reliable means of isolating power sources to prevent accidents and electrical hazards.

3. Industrial Applications:

In industrial settings, AC isolator switches are utilized in a variety of applications, including motor controls, machinery, and power distribution systems. They provide a means of isolating power sources to equipment and machinery during maintenance or repair activities. AC isolator switches are crucial for ensuring the safety of workers and preventing damage to equipment in industrial environments.

4. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems rely on AC isolator switches to disconnect power to the system for maintenance or servicing. These switches are typically installed near the HVAC equipment to provide easy access for technicians. AC isolator switches ensure the safe handling of HVAC systems and prevent the risk of electric shock or injury during maintenance procedures.

5. Data Centers and Telecommunications Infrastructure:

In data centers and telecommunications facilities, AC isolator switches are used to isolate power to critical equipment and servers. They provide a means of disconnecting power sources for maintenance, repair, or emergency shutdowns. AC isolator switches help ensure the uptime and reliability of data center operations by facilitating safe maintenance procedures.

Conclusion

In conclusion, isolator switches play a pivotal role in ensuring the safety, reliability, and efficiency of electrical systems across various applications and industries. Whether in residential, commercial, industrial, or specialized settings, isolator switches provide a vital means of isolating power sources for maintenance, repair, or emergency shutdowns.

The importance of selecting the appropriate isolator switch for a specific application cannot be overstated. Factors such as voltage and current ratings, environmental conditions, and compliance with safety standards must be carefully considered to ensure optimal performance and reliability.

Furthermore, proper installation, maintenance, and adherence to safety protocols are essential to maximize the lifespan and effectiveness of isolator switches. Regular inspections, testing, and following manufacturer guidelines can help prevent accidents, ensure compliance, and extend the service life of isolator switches.

FAQ`s.

1. What is the difference between an isolator switch and a circuit breaker?

While both isolator switches and circuit breakers serve to disconnect electrical circuits, they operate differently. An isolator switch provides a physical disconnect, manually breaking the electrical connection to isolate the circuit. In contrast, a circuit breaker automatically trips in response to overcurrent or short circuits, interrupting the flow of electricity to protect the circuit.

2. Can isolator switches be used for emergency shutdowns?

Yes, isolator switches are commonly used for emergency shutdowns to quickly disconnect power in hazardous situations. They provide a reliable means of isolating power sources to prevent accidents or damage to equipment during emergencies.

3. Are isolator switches suitable for outdoor installations?

Many isolator switches are designed for outdoor use and are rated for weatherproofing to withstand exposure to the elements. These switches feature robust construction and sealing to protect against moisture, dust, and other environmental factors.

4. Do isolator switches require regular maintenance?

Yes, like any electrical component, isolator switches may require periodic maintenance to ensure proper functioning. Regular inspection and testing can help identify any issues or signs of wear and tear, allowing for timely repairs or replacements as needed.

5. Can isolator switches be locked in the off position?

Yes, many isolator switches feature provisions for padlocks or lockout/tagout devices to prevent accidental activation. Locking the isolator switch in the off position ensures that power cannot be restored without proper authorization, enhancing safety during maintenance or repair procedures.

Derek Ke

Hi, I’m Derek Ke, founder of Moreday.com, an expert in solar-protected electrical products and electric vehicle charging.

Over the past 15 years, we have helped nearly 500 customers (such as farms, residential, industrial, and commercial) in 60 countries solve new energy and green power problems. We aim to share more knowledge about solar power generation and new energy with everyone so that green electricity can enter thousands of households.