Introduction

I

n the fast-paced world of electric vehicles (EVs), one term that’s gaining significant traction is “battery cycle life.” But what does it mean, and why is it so crucial? As the backbone of EV technology, the battery’s performance and durability are pivotal to the vehicle’s success. This article takes a deep dive into the intricacies of EV power battery cycle life, uncovering its importance, testing methodologies, challenges, and future prospects. So buckle up and let’s explore what makes these powerhouses tick.

EV Power Battery Cycle Life

Let’s kick things off by understanding what cycle life is. In simple terms, the cycle life of a battery refers to the number of complete charge and discharge cycles it can undergo before its capacity falls below a specified percentage of its original value. Think of it as the lifespan of your EV battery. Every time you charge your EV and then drive it until it needs to be charged again, that’s one cycle.

But why is this important? Well, the cycle life directly impacts how long your EV battery will last before it needs to be replaced. And given that the battery is one of the most expensive components of an electric vehicle, a longer cycle life means more bang for your buck. It’s no surprise, then, that manufacturers and consumers alike are laser-focused on this aspect.

Understanding Battery Degradation

Now that we’ve got a handle on what cycle life is, let’s dig into what causes batteries to degrade over time. Just like your smartphone battery seems to lose its mojo after a couple of years, EV batteries aren’t immune to the wear and tear of daily use.

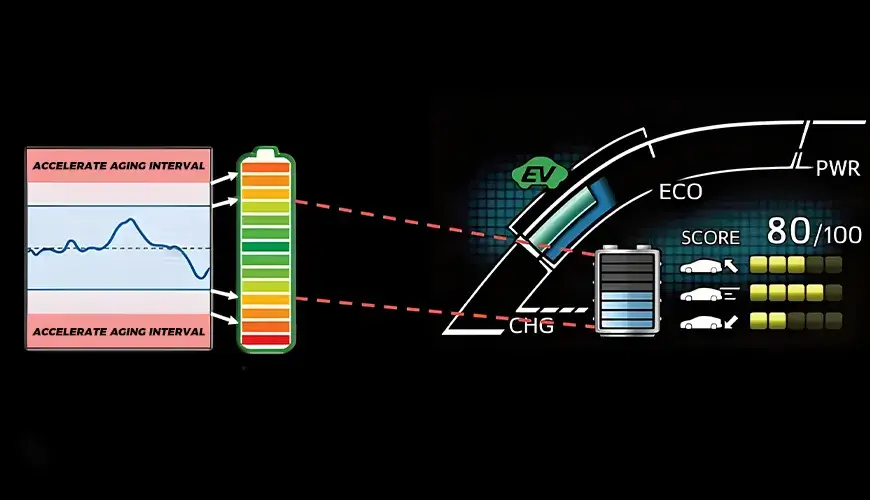

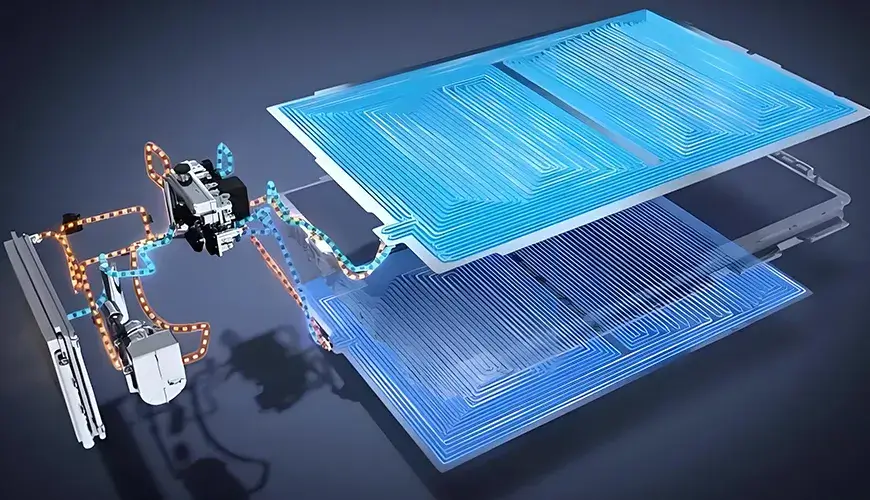

The main culprits behind battery degradation are the conditions under which the battery operates. High temperatures, frequent fast charging, deep discharges, and even the age of the battery all contribute to its gradual decline. Over time, these factors lead to a reduction in the battery’s ability to hold a charge, which in turn shortens its cycle life.

To put it simply, every time you push your battery to its limits—whether it’s by driving long distances in scorching heat or constantly using fast chargers—you’re shaving off a bit of its overall life. This is why understanding how to optimize battery usage is key to extending its cycle life.

Battery Cycle Life Test

Battery cycle life is an important parameter to measure battery performance. The definition of battery cycle life is: the number of cycles that a battery can withstand before its capacity drops to a certain specified value under a certain charge and discharge system. Factors that affect the battery cycle life include electrode materials, electrolytes, diaphragms, manufacturing processes, charge and discharge systems, and ambient temperature. When conducting cycle life tests, the test conditions must be strictly controlled.

Standard cycle life: Standard cycle life means that when the test sample is subjected to a standard cycle life test according to the prescribed method, the discharge capacity should not be less than 90% of the initial capacity when the cycle number reaches 500 times, or the discharge capacity should not be less than 80% of the initial capacity when the cycle number reaches 1000 times.

Operating cycle life: The operating cycle life varies depending on the type of electric vehicle.

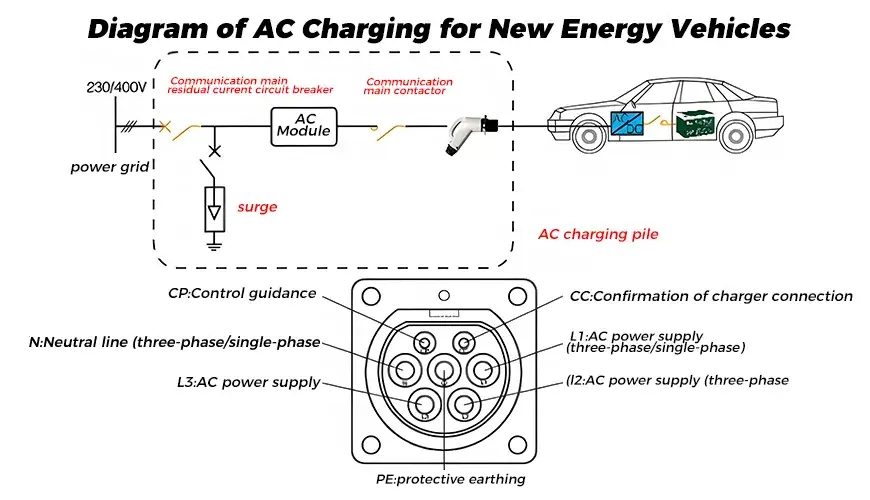

EV Power Battery Charging Method

At room temperature, charge according to the charging method specified by the company. If the company does not provide a charging method, charge according to the following method:

For lithium-ion batteries, charge at a constant current of 1l₁(A) to the charging termination voltage specified by the company, then switch to constant voltage charging, and stop charging when the charging termination current drops to 0.05l₁(A). After charging, leave it alone for 1 hour.

For nickel metal hydride batteries, charge at a constant current of 1l₁(A) for 1 hour, then charge at 0.2l₁(A) for 1 hour, and let stand for 1 hour after charging.

Note: The test method can be found in GB/T 31485-2015-Safety requirements and test methods for power batteries for electric vehicles.

EV Power Battery Capacity and Energy Test Method

1. Discharge at 11 (A) current to the discharge termination condition specified by the enterprise.

2. Leave for no less than 30 minutes or the shelf time specified by the enterprise.

3. Charge according to the charging method.

4. Leave for no less than 30 minutes or the shelf time specified by the enterprise.

5. Discharge at 1l₁ (A) current to the discharge termination condition specified by the enterprise.

6. Calculate step ⑤ discharge capacity (in A*h) and discharge energy (in W*h).

Standard Cycle Life Test Method for Power Batteries

1. Discharge at 1l₁(A) current to the discharge termination voltage specified by the enterprise.

2. Leave for no less than 30 minutes or leave under the conditions specified by the enterprise.

3. Charge the battery according to the charging method.

4. Leave for no less than 30 minutes or leave under the conditions specified by the enterprise.

5. Discharge at 1l₁(A) current to the discharge termination condition specified by the enterprise and record the discharge quantity.

6. Cycle 500 times continuously according to ②~⑤. If the discharge capacity is higher than 90% of the initial capacity, terminate the test; if the discharge capacity is lower than 90% of the initial capacity, continue to cycle 500 times.

7. Measure the discharge capacity and discharge energy at room temperature.

Lithium Cobaltate | Lithium Manganate | Lithium Nickel-Cobalt-Manganese | Lithium Nickel-Cobalt Aluminum Oxide | Lithium Iron Phosphate | |

Acronym | LCO | LMO | NCM | NCA | LFP |

Theoretical Specific Capacity | 274mAh/g | 148mAh/g | 278mAh/g | 274mAh/g | 170mAh/g |

Actual Specific Capacity | 150mAh/g | 110mAh/g | 160mAh/g | 180mAh/g | 120mAh/g |

Discharge Voltage | 2.7~4.3V | 2.7~4.3V | 2.7~4.3V | 2.5~4.3V | 2.5~3.8V |

Cycling Performance | Better | Average | Better | Better | Good |

First Irreversible Loss | 5% | 5% | 10% | 10% | 15% |

Safety | Worse | Good | Better | Average | Very Good |

High Temperature Performance | Good | Average | Better | Average | Good |

Low Temperature Performance | Better | Average | Better | Better | Poorer |

Transition Metal | Poor | Rich | Poor | Average | Very Rich |

Power Battery Operating Cycle Life

The cycle test of energy-type batteries for pure electric passenger vehicles consists of two parts. The charging part is carried out according to the charging method, and the discharging part is carried out according to the main discharge conditions in the table below. The schematic diagram of the large cycle SOC fluctuation of energy-type batteries for pure electric passenger vehicles is shown in the figure below.

| time increment/s | Cumulative Time/s | Current/A | ΔSOC/% |

| 5 | 5 | 3I₁ | -0.417 |

| 3 | 8 | -I₁ | -0.333 |

| 6 | 14 | -⅓I₁ | -0.278 |

| 40 | 54 | ⅓I₁ | -0.648 |

| 30 | 84 | ½I₁ | -1.065 |

| 10 | 94 | I₁ | -1.343 |

Operating Cycle Test Method for Energy Storage Batteries for Pure Electric Passenger Vehicles

1. Charge according to the charging method

2. Leave for 30 minutes

3. Run the main discharge condition until 20% SOC or the minimum SOC value specified by the enterprise, or the discharge termination condition specified by the enterprise

4. Leave for 30 minutes

5. Repeat steps ①~④ for a total of xh (x is about 20 and the number of cycles is an integer multiple of the large cycle shown in Figure 1)

6. Leave for 2h

7. Repeat steps ①~⑦ for a total of 6 times

8. Test the capacity and energy according to the capacity and energy test method

9. Calculate the ratio of the total discharge energy to the initial energy of the battery

10. Repeat steps ①~⑨ until the ratio of the total discharge energy to the initial energy of the battery reaches 500

Energy Storage Battery Cycle Test for Pure Electric Commercial Vehicles

It consists of two parts. The charging part is carried out according to the charging method, and the discharging part is carried out according to the main discharge conditions in the table below. The schematic diagram of the large-cycle SOC fluctuation of the energy-type battery of a pure electric commercial vehicle is shown below.

| time increment/s | Cumulative Time/s | Current/A | ΔSOC/% |

| 23 | 23 | I₁ | -0.639 |

| 8 | 31 | ⅓I₁ | -0.713 |

| 23 | 54 | -⅓I₁ | -0.500 |

| 26 | 80 | 0.1I₁ | -0.572 |

Test Method

1. Charge according to the charging method

2. Leave for 30 minutes

3. Run the main discharge condition until 20% SOC or the minimum SOC value specified by the enterprise, or the discharge termination condition specified by the enterprise

4. Leave for 30 minutes

5. Repeat steps ①~④ for a total of xh (x is about 20 and the number of cycles is an integer multiple of the large cycle shown in Figure 1)

6. Leave for 2h

7. Repeat steps ①~⑦ for a total of 6 times

8. Test the capacity and energy according to the capacity and energy test method

9. Calculate the ratio of the total discharge energy to the initial energy of the battery

10. Repeat steps ①~⑨ until the ratio of the total discharge energy to the initial energy of the battery reaches 500

Role of Testing

As battery technology continues to evolve, so too will the methods used to test them. With advancements in predictive models and deep learning, testing is expected to become faster, more accurate, and more cost-effective, helping to accelerate the development of new battery technologies.

Conclusion

In conclusion, the cycle life of an EV battery is a critical factor that impacts everything from the performance of the vehicle to the cost of ownership. While there are challenges associated with testing and improving cycle life, advancements in technology are helping to overcome these hurdles. With ongoing research and development, the future of EV batteries looks promising, with longer-lasting, more sustainable, and better-performing batteries on the horizon.

Recommended reading: Main Types of EV Power Batteries

Derek Ke

Hi, I’m Derek Ke, founder of Moreday.com, an expert in solar-protected electrical products and electric vehicle charging.

Over the past 15 years, we have helped nearly 500 customers (such as farms, residential, industrial, and commercial) in 60 countries solve new energy and green power problems. We aim to share more knowledge about solar power generation and new energy with everyone so that green electricity can enter thousands of households.