An aerosol fire suppression system is a modern fire protection solution designed to extinguish fires quickly and effectively in enclosed and equipment-dense environments. As electrical cabinets, energy storage systems, and control panels become more compact and powerful, traditional fire suppression methods such as water or gas systems are often impractical. Aerosol fire suppression has therefore emerged as a reliable and space-efficient alternative.

This article explains what an aerosol fire suppression system is, how it works, its main components, and why it is widely used in electrical and energy-related applications.

What Is an Aerosol Fire Suppression System?

An aerosol fire suppression system is a fixed fire extinguishing system that suppresses fire by releasing a fine aerosol composed of microscopic solid particles suspended in gas. Unlike water-based or gaseous systems, aerosol fire suppression primarily works through chemical interruption of the combustion process, rather than cooling or oxygen displacement alone.

Aerosol systems are typically installed directly inside the protected enclosure, such as an electrical cabinet or battery compartment, allowing them to suppress fire at the earliest stage, close to the ignition source.

Main Components of an Aerosol Fire Suppression System

Although compact in size, an aerosol fire suppression system includes several key components:

- Aerosol generator: The core unit that produces the fire-extinguishing aerosol when activated.

- Aerosol-forming compound: A solid agent that reacts in a controlled manner to generate condensed aerosol particles.

- Activation mechanism: Can be thermal (heat-sensitive) or electrical, triggered by a fire detection system.

- Housing and mounting accessories: Designed for safe installation inside enclosures.

- Optional detection and control interface: Used in systems requiring monitoring, alarms, or remote activation.

Most cabinet-level aerosol systems are self-contained and do not require external piping, cylinders, or pressure vessels.

How Does an Aerosol Fire Suppression System Work?

When a fire occurs, the aerosol fire suppression process follows several rapid steps:

- Detection or Heat Activation

The system is activated either by a built-in thermal element or by a signal from an external fire detection device. - Aerosol Generation

The aerosol generator initiates a controlled reaction of the solid compound, producing large quantities of condensed aerosol particles. - Aerosol Dispersion

The aerosol expands and fills the protected enclosure, distributing evenly throughout the space. - Fire Suppression

The aerosol particles interrupt the chemical chain reactions of combustion by neutralizing free radicals in the flame, rapidly suppressing the fire.

This process typically extinguishes fire within seconds, even in energized electrical environments.

Why Aerosol Fire Suppression Is Effective in Enclosed Spaces

Aerosol fire suppression systems are especially effective in enclosed or semi-enclosed areas because:

- The aerosol remains concentrated within the enclosure

- Small quantities of agent achieve high extinguishing efficiency

- Fire is suppressed at an early stage

- No pressure-tight room sealing is required

These characteristics make aerosol systems ideal for electrical cabinets, battery enclosures, and equipment housings.

Types of Aerosol Fire Suppression Systems

Condensed Aerosol Fire Suppression Systems

Condensed aerosol systems generate solid aerosol particles that remain suspended long enough to effectively suppress flames. They are widely used in electrical and electronic applications where space is limited.

Thermal Aerosol Fire Suppression Devices

Thermal aerosol devices rely on heat-sensitive activation and operate independently, making them suitable for standalone cabinet protection without external detection systems.

Aerosol Fire Suppression vs Traditional Fire Suppression Methods

Aerosol vs Water-Based Systems

Water-based fire suppression systems can cause severe damage to electrical equipment and are not suitable for energized environments. Aerosol fire suppression extinguishes fire without introducing conductive liquids.

Aerosol vs Gas Fire Suppression Systems

Compared with gas-based fire suppression systems, aerosol systems:

- Require significantly less installation space

- Do not rely on pressurized cylinders

- Are easier to retrofit into existing equipment

- Provide cost-effective localized fire protection

Typical Applications of Aerosol Fire Suppression Systems

Aerosol fire suppression systems are commonly used in:

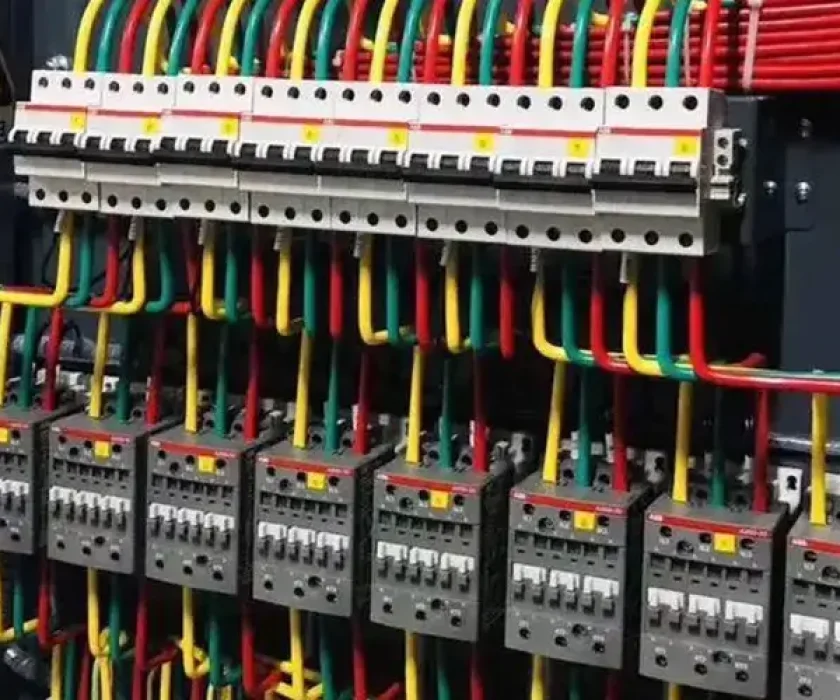

- Electrical distribution cabinets

- Control panels and PLC enclosures

- Solar PV combiner boxes

- Energy storage system (ESS) battery cabinets

- Telecom and data communication cabinets

- Industrial automation equipment

These applications benefit from fast, automatic fire suppression without complex infrastructure.

Safety, Standards, and Compliance

Modern aerosol fire suppression systems are designed to meet relevant international safety and performance standards. Important considerations include:

- Fire extinguishing effectiveness

- Electrical compatibility

- Toxicity and residue control

- Long-term stability and service life

Always verify certifications and test reports before deploying aerosol fire suppression in critical systems.

How to Choose the Right Aerosol Fire Suppression System

When selecting an aerosol fire suppression system, consider the following factors:

- Volume of the protected enclosure

- Type of fire risk

- Activation method

- Installation environment

- Applicable standards and certifications

Correct system selection ensures reliable fire protection and long-term operational safety.

Conclusion

An aerosol fire suppression system provides fast, efficient, and space-saving fire protection for modern electrical and energy systems. By chemically interrupting combustion and suppressing fire at an early stage, aerosol technology offers a reliable alternative to traditional fire suppression methods.

For applications such as electrical cabinets, control panels, and energy storage systems, aerosol fire suppression has become a practical and proven solution.