JIANGSU YUEYANG BIPV FACTORY PROJECT

DATE: September 27, 2021

LOCATION: Jianhu, Jiangsu

NAME:Yueyang BIPV

INSTALLED CAPACITY: 4.56MW

01. Description

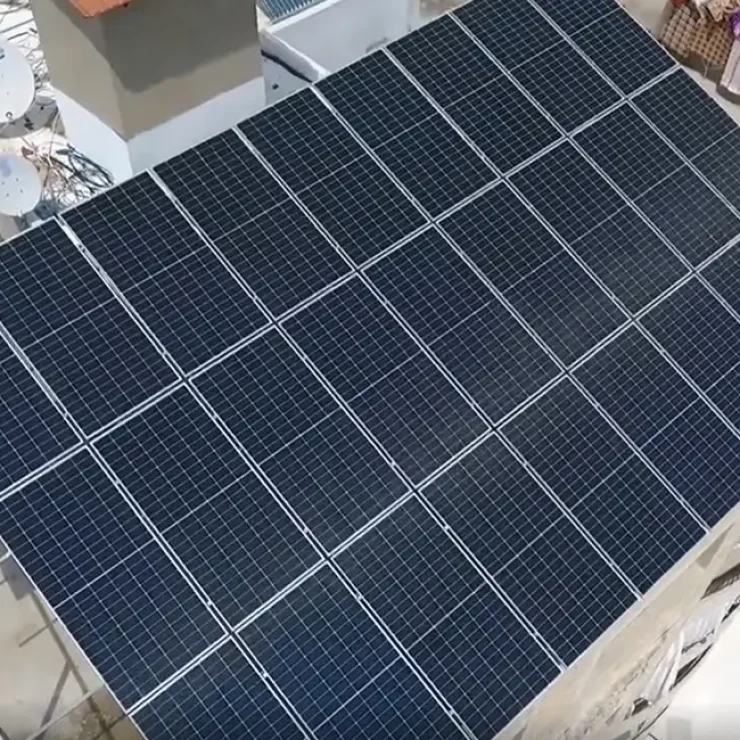

T he Yueyang Phase II BIPV roof project is located in the Phase II factory of Jiangsu Yueyang PV Technology Co., Ltd. in the Jianhu County High-tech Zone. It is invested and constructed by Jiangsu New Sunshine Smart Top Technology Co., Ltd. The total investment of the project is 19.6 million yuan, with a roof area of 33,320 square meters, including a warehouse roof area of 29,400 square meters and an awning area of 3,920 square meters. It uses 12,012 customized 380-watt monocrystalline modules, with a total installed capacity of 4.56MW.

The project will generate approximately 5.37 million kilowatt-hours of electricity in the first year after it is put into operation, and the total power generation in the 25-year life cycle will reach 125 million kilowatt-hours. In 25 years, a total of 45,000 tons of standard coal can be saved, CO2 emissions can be reduced by 120,000 tons, SO2 emissions can be reduced by 3,800 tons, and NOX emissions can be reduced by 19,000 tons. If calculated based on a tree absorbing 16 kilograms of CO2 per day, it is equivalent to planting 820 trees.

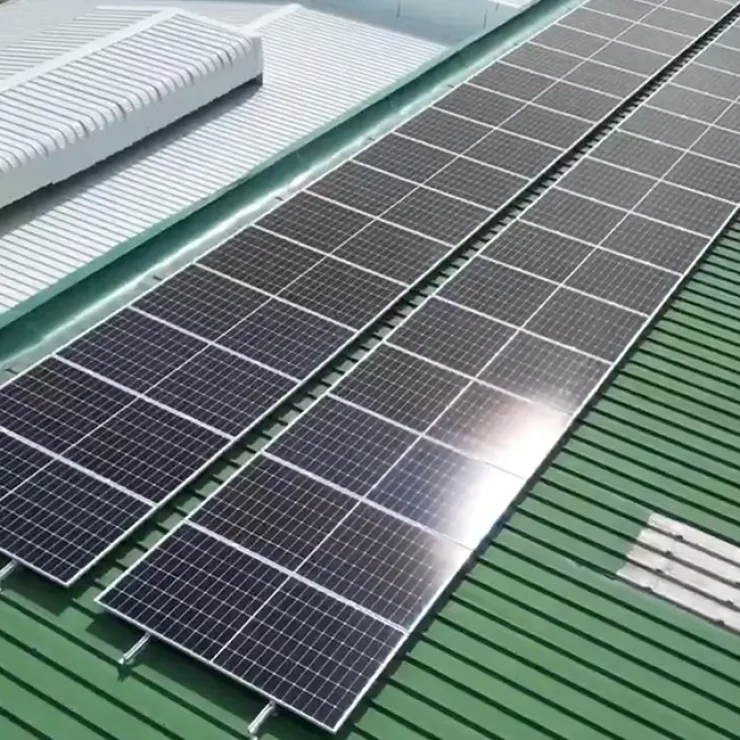

The project directly uses the BIPV structure to replace the color steel tiles as the building roof, achieving three photovoltaic building integration technologies: the photovoltaic life is longer than the color steel tile structure, the lighting is better than the color steel tile structure, and the comprehensive cost is lower than the color steel tile structure. breakthrough.

The smooth connection of the first BIPV demonstration project to the grid for power generation has also pressed the “acceleration button” for the advancement of rooftop distributed photovoltaics in Jianhu County. In the next stage, our company will continue to accelerate the application of distributed photovoltaics and actively expand ” “Photovoltaic +” application scenario ensures high-quality completion of pilot work and helps achieve carbon peak and carbon neutrality.

02. solutions & tips

The overall planning of the factory is based on the production flow line, with raw material warehouses, workshops, and finished product warehouses arranged in sequence from north to south. The three buildings are connected by a glass corridor for ease of use. Slightly different from traditional factories, the factory in this case is huge. Taking the intermediate factory as an example, it covers an area of 58,000 square meters and is 295 meters long from north to south. How to deal with such a large-scale building has become a difficulty in this design.

The largest single BIPV factory project in China is under construction and is connected to the grid for power generation.• ANDONG JIA

After many rounds of comparisons of plans, the designer found that compared to complex shape design, simple and light design techniques are more conducive to reducing the sense of oppression caused by the huge volume. It adopts a segmented design, with dark gray at the bottom and light gray at the top, creating a light and floating feeling to weaken the larger volume of the building. On the first floor of the building, a window sill height of 1.2 meters is adopted, and above it, a long window with a height of 1.8 meters is adopted, which is mainly comfortable and close to people and easy to use, thus weakening the strong difference in volume. The building’s large area of light gray horizontal corrugated metal panels makes the facade more modern. At the same time, as the angle of the sun changes throughout the day, delicate and changeable light and shadow effects are presented.

Among the above two methods, the combination of photovoltaic arrays and buildings is more common, and this project adopts the method of integrating photovoltaic arrays and buildings, making photovoltaic panels an integral part of the building and enhancing the beauty and technology of the building. feel.

The roof of the finished product warehouse of the project innovatively uses photovoltaic panels directly as the roof, which can be intuitively felt from the inside. The roof is divided into small units according to column spans. The roof faces the sun and is arranged diagonally in units to maximize the absorption of solar energy and improve the efficiency of photovoltaic power generation. The project uses 12,020 380W monocrystalline modules to form a BIPV panel roof with a total construction area of 33,000 square meters.

Taking into account the problem of rising room temperature caused by directly using photovoltaic panels on the roof, the plan is to arrange electric opening windows at the highest point of the sloped roof at each span. Together with the windows at the bottom against the outer wall, a thermal pressure effect is formed, and the upper part is heated The air is exhausted and the cold air from the lower part is supplied. Let the building “breathe” freely, thereby effectively reducing room temperature. Implement the green, environmentally friendly and low-energy design concept, reflect corporate social responsibility, and respond to the government’s call for carbon peaking and carbon neutrality.